Have you noticed if temperature of the actual mash was higher than what is measured at the tee? I noticed a couple of degree celsius difference, mash was higher than tee. Just curious if I am the only experiencing this or if it is normal in this type of setup.

Actually it was the other way round, the temp in the grains was a bit lower than what was measured at the tee, which I guess is normal.

I’m a happy brewpi customer and have been using the spark for fermentation for a while. Like many, I have been eagerly following @Elco’s progress since I’m keen to set up a HERMs or RIMs system.

Looking at the graphs Elco posted, I immediately noticed the slow ramp-up times (0.33 deg/min). I too will be limited to a 3200w element, with similar volumes. However, this BYO mag article suggests temperature rises slower than 1 deg/min (during a stepped mash) can adversely affect head retention. One way to speed the heat times up would be to have the HLT at sparge temp (82 deg) before starting the mash. However as the article suggests, the HERMS coil will need to be bypassed when the mash temp exceeds the desired level.

I notice the HERMS schematics on Github don’t have this bypass loop. @Elco do you think brewpi will be able to handle this in the future? I guess I could always use a RIMs instead, however a HERMS makes sense to me if I already need to have a heater in the HLT.

Also, do you have any plans to sell 3-way motorised ball valves?

I know, I thought it would be the opposite as well, instead I guess the flow rate of the pump cools the wort before returning to the mash. Was just curious to see if anyone else had the same experience.

So I use:

114L blichmann pot with a grain bag.

This is recirculated continuously through a CCFC (exchilerator).

A 15L ‘HLT’ supplies the other side of my hex.

I too have noticed a 2 degree difference between my mash probe and my tee. I am needing to do some research into this, but I believe it is simply a higher temp in the grain bed due the thermal mass and insulating properties of the grain itself. I don’t know what effect this has on your wort though. I.e; what has the greatest effect on fermentability of your wort, the grain bed temp, or the temp of the liquor flowing around it? Anyone know? Also, what is causing some people to have the inverse situation?

My probes are placed as per elco’s water test above. Except I’ve had my room temp inside the blichmann’s thermowell measuring the grain temp as above.

I’m thinking I might test having my beer probe at the return to my MT?

Anyhow, I am pleased I’m having good results and this is enjoyable hypothesising and tinkering!

@cke11y @Luca @brianpedersen I’m wondering if you checked the temperature of the grain bed in multiple locations (i.e. does it vary?), or was it fixed in a thermowell?

I’m wondering if some of the discrepancy between the grain bed and the tee are just normal variation in the probes (particularly since @brianpedersen reported it being a bit higher in the tee, while others lower) . I know one of my brewpi temp probes measures about 0.6 degrees higher than the other two.

Also, to be safe I guess you could use the average of both mash probe and tee probe as the input to the PID as mentioned in @Elco’s previous post.

As an aside, I’m curious to know how consistent the temperature is across the grain bed, with a standard stainless pot, standard false bottom and typical flow rate. I’m about to buy a new mash tun for my HERMS set up and I’m not sure if insulation would be beneficial or just a waste of money.

My mash was pretty wet, so the temp was consistent all over the grain bed.

The probes has been compared in a glass of water, and they are within 0.5 degree celcius, of each other.

There are many variables to counter for, which is why a probe in the grain bed is a good thing

The temperature in the grain bed has been checked and resulted consistent in different locations, also probes are accurate and measure correctly. I think @cke11y is right and the difference in temperature is due to the thermal mass of the grain bed as opposed to the fast flowing wort in the tee. I have placed the probe in the tee both at the kettle valve and at the top before returning to the kettle, but didn’t see much difference in reading (will test again this week to be sure). So in conclusion should I consider the probe that gives me the highest temperature and set brewpi in fridge constant mode on that sensor? I have also tried using “beer constant” and set the fridge as the tee probe and the beer as the mash probe, this gave me good results with water but tended to overshoot with actual mash. My BIAB setup consists of a 75 L kettle, with a 5500 watt element and recirculating topsflo pump.

This is a very similar setup to what I am building (BIAB, with recirc pump, 60L with 5500W element) so I’m keen to see how you progress with optimising settings etc.

Yeh I only have about 0.5 variance in probes too. I haven’t checked my temps at multiple levels in the tun, but I honestly believe that decent re-circulation results in pretty low chance of significant stratification. Could be wrong though.

I’m actually thinking I will alter my probe placement based on the beer Im brewing. If I want dry, I will probably use the grain bed temp as beer probe, but if I’m happy to have less fermentables in a brew, I might use the tee? Difficulty here, is changing processes and not having consistency to be able to make comparisons on a very loose scientific basis…

Hi Elco

Can you please advise me, where I can find this 2 options:

- Controlling a heater directly, based on your mash sensor

- Cascaded control: your HLT setpoint is adjusted automatically based on your mash temperature.

I was looking in the maintenance panel --> advanced settings, but I could not find any thing like this?

I did an update to the newest release.

Thanks in advance.

When a fridge sensor (=HLT sensor) is available, the heater1 PID will take the HLT as input sensor.

With the latest beta, if you do not connect a fridge sensor, heater1 will be controlled by the beer temperature (it falls back on the beer temp in absence of a fridge temp).

So to run without a HLT/fridge temperature, disconnect the fridge sensor and set Kp, Ti and Td for the beer-to-fridge PID to zero, so the fridge/HLT setting equals the beer setting. Then just configure the heater1 PID.

If you run with a HLT sensor, the beer-to-fridge PID output will be added to the beer setpoint to give the HLT setpoint. The heater1 PID then controls the HLT to keep that automatically adjusted setpoint.

ok, I will try to check this out, thanks for your answer. Another thing, is it possible to change the Time from days to hours in beer profiles? my recipe goes from 57° over 63°, 72° to 78°and I’d like to create a profile for this?

You can type 1h20m15s in the profile.

With new beta firmware, in this case what is the bes value for “Heater 1 PWM period (seconds)” parameter?

Depends on your type of heater, but if it is a purely restive heater, I think the default of 4 seconds should be fine. Gives you nice granular control.

I have a Herms system with 80L ThermoPot and a pump with 5L/min recirculation (real data) in HLT.

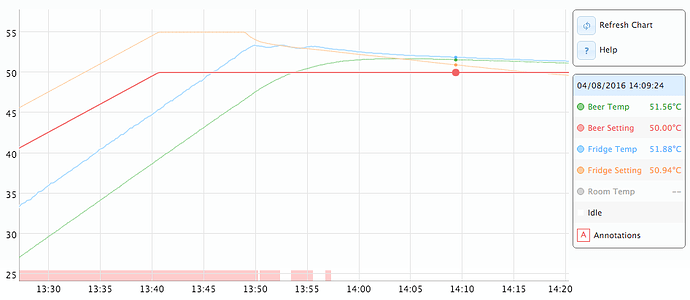

In my first test I had an important overheating, I caused the isolation of the pots.

What values should I adjust? Now i used the Elco configuration

Confused here. The screen shots look like the old BrewPI fermentation screens, not what I would expect to see for brewing. This brings up a concern on processing for me. My set up has 2 fermentation chambers, looking forward to the activation update, and a HERMS system that makes 10 gallon batches (Blichmann 20 gallon pots). So my concern is if I have my BrewPi Sparc system normally connected to my fermenters (1 full 1 empty) what happens to the system when I plug in my brew system to make a batch of beer to go into the empty fermenter?

Thanks in advance

Kead, Can you try with 0.4.3? It is out of beta now.

It should have a lot less overshoot than 0.4.2.

What is the volume of your RIMS tube? What is the power?

Is the fridge temp the output temp of your RIMS?

mmmooretx, they screen shot does look a lot like fermentation, because the web UI has not had an update yet.

There is not yet an easy way to dump and restore settings/devices. Switching from fermentation to mashing would require changing the settings manually, sorry.