I am answering a question in another thread, but thought this might spark some more discussion so a separate thread would be better.

I have made a dual valve controller to control motorized ball valves via OneWire.

With this board, many ball valves can be connected directly to the BrewPi Spark. They are controlled and powered via the RJ12 ports.

I designed the boards to make wiring everything a lot easier. I have 12 valves in my setup and I don’t want to run a wire to each one from the control panel. In the bottom photo, the leftmost wire is from the control panel and all the wires that go over the rail are temperature sensors.

The valve controller is built from a OneWire 8 channel switch (DS2408) and a dual H-bridge (SN754410, L392D equivalent).

The OneWire switch drives the dual H-bridge with 4 pins and can read the feedback switches inside the valves with the other 4 pins.

Each valve has 4 status LED’s: open, closed, opening, closing. The opening and closing LEDs are parallel to the motor, the open/closed LEDs are switched by the feedback switches inside the valve.

This board is designed for CR-501 valves:

These valves have 2 feedback switches and can be actively closed and opened. The motor automatically stops when they are fully open or closed, but it can also be stopped in between. With the feedback signals, BrewPi could measure how much time it takes to go from fully open to fully closed and could potentially stop in between as well.

The boards and valves can be powered from the RJ12 bus on the BrewPi Spark, they require little current. This makes wiring very easy: they can be daisy chained and each board will have 2 places free for extra temperature sensors (see first photo).

The board could also be used for 30x valves, by driving the H-bridge with 11/10 or 00/01 instead of 10/01. You will not have the feedback signals and cannot open the valve half-way. This is the downside of the 30x valves and the reason I picked 501.

Here is the schematic of the board:

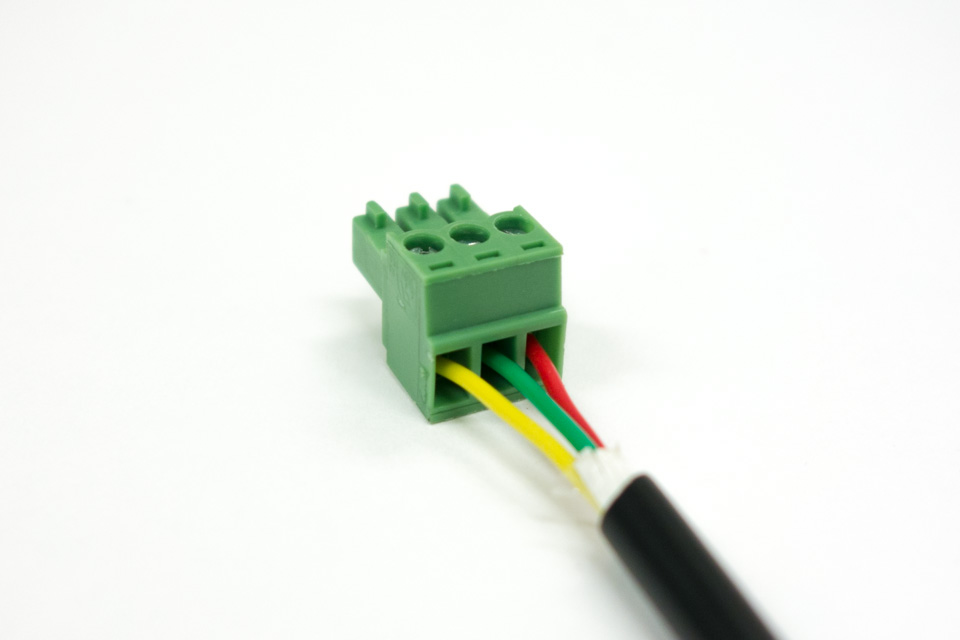

So far I only made 15 prototype boards, but I plan to start selling these board and CR-501 valves in about a month. I will sell the valves with connectors already assembled, you only have to plug them into the controller board.

One issue that I still have not figured out is how to make the enclosure for these. These boards would benefit form a waterproof enclosure, being close to valves/fittings etc. Entirely waterproof is not possible, because the connectors are not waterproof, but at least it should be protected from splashing water.

How can I make a waterproof enclosure, but keep the status LEDs visible?

One option would be to use a transparent plate on top. I have not figured out a better alternative yet.

How can these boards be attached to the valves?

Maybe a good idea would be to assemble PCB and enclosure with one or 2 pipe clamps like this:

Another thing to keep in mind is that the enclosure should be able to handle 100C temperatures.

Any feedback and ideas are very welcome!

I will keep my thinking cap on though.

I will keep my thinking cap on though.