Hey all,

Im hoping someone could help me tune my PIDs correctly. I Recently aquired a new fridge and decided to upgrade to BrewBlox and I am impressed but I am having a hard time getting dialed in. I have a beer in the chamber now and want to ferment at 69F for the duration of the ferment but i am overshooting. I was originally overshooting on the cold side so i lowered my Fridge Kp to -1.5( It is a Monster Merchendiser fridge) That helped a lot but now i over shot to the hot side by like 5-6 degrees. This happened before with the cold side but why keep heating/cooling after reaching the setpoint? The chart doesn’t really show a drive like that. What values would you look at to get an idea of what to change next? Very impressed with the update just need to do some real tuning. Hence why i made a forgiving beer to tune to.

Are you using fridge or beer mode?

The most interesting graphs for tuning are the heating cooling PIDs’. Click on the blue cooling icon or red heating icon in the bottom right of the fridge diagram to open PID settings.

In there, in the top right corner is a dropdown button where you can view the PID graph.

Overshoot is often caused by the integrator part of the PID which is too high because the setpoint was not reached for a long time. That could be caused by the P part (Kp) being too low. Try increasing Kp and see if that helps.

Trial with a waterfilled bucket before using it for an actual fermentation!

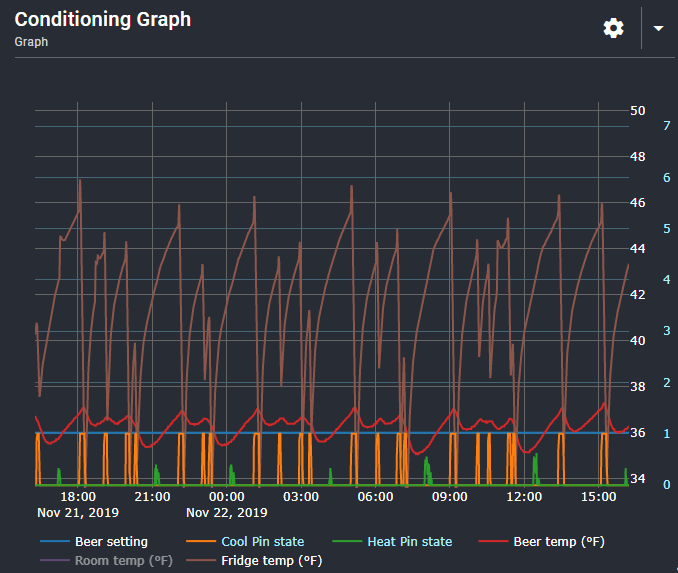

I am trying to keep a constant 36F in my cold conditioning setup. When I run my setup with the default settings I see the temp spend most of its time above 36F, with the occasional drop below 36F, which then kicks the heater on and we go way up to about 37.5F.

This creates an inefficient set of temp swings, compared to what I used to see in the BrewPi days. So I’m thinking about these changes and would appreciate some feedback:

- set Kp/Ti/Td = 0 for the heater PID, as a means to disable the heater altogether

- set Ti = 0 and Td = 0 for the cooling PID, and basically entrust Kp to do all of the work

Note: I don’t care much if I go a little below 36, which is why I’m OK to disable the heater PID altogether and let the ambient air be my heater.

What is your setup? Do you have much/any insulation?

You can probably address a lot with PID tuning, but I can’t help but notice that the bridge temperature starts rocketing up well before the heater turns on–implying that inadequate insulation may be an issue.

To disable the heater, just disable the heater PID and leave the other settings on their normal values.

To prevent heating after cooling, set a higher idle time in the mutex.

But in general, your PID settings seem way off.

What did you change compared to the defaults? Can you remove the blocks and recreate them using the fermentation wizard?

Then share the PID grahps.

First I will describe my conditioning setup:

- several filled 1/6th-barrel kegs stacked in an upright freezer

- the fridge temp sensor sits at about mid-height in the freezer, and close to the middle of the space. It simply dangles off the handle of one of the kegs.

- the “beer” temp sensor (the setpoint sensor) sits on the interior floor of the freezer, in a large Mason jar filled with water. I could move it up higher but inevitably it gets knocked over and then I have a mess to clean up!

- the heater is a ceramic “mat” heater (https://images.app.goo.gl/U2PN21xZNcNw9YDN9). But I don’t lay it flat in the freezer; it is propped rather more vertically at one side of the freezer down at the floor level

- the freezer is about 5 years old, so the compressor and insulation are in decent shape

- I haven’t modded the freezer, so there are OneWire sensor cables that keep the rubber gasket from closing completely around the full frame of the door. That’s my most obvious source of heat loss, beyond the usual loss from being in a room that is 75F+ all day long (it’s where my home’s boiler and water heater are)

This same setup is where I did conditioning with a BrewPi (as little as a month ago), and typically saw fewer temp swings, which is why I assume some PID adjustments are in order.

This same setup is also where I put my 1-bbl conical when it comes time to ferment, at which point my expectations on temp control get more stringent.

Also, I did not change the PID settings from their defaults. Well, not until about 12 hours ago that is!

The defaults set by the ‘constant beer temp’ quick action are chosen to work well for at least 20L of beer.

If you have your sensor in a mason jar, you are better off using the fridge settings.