@Elco , permanently? or just for cleaning?

i looked into the CIP ball and that seems pretty awesome… thinking of creating something smart for this

no just put it on the hose for cleaning, not permanently.

i’m thinking to put one in both the boil and the mash kettle but then attached to the lid… then start the flushing but start feeding it through the CIP ball in the kettle lid then switch to sending it through the hoses so that i have a good flush…

so. since it’s been quiet for a while… i have actually beenbuilding. will build a bit more next week and update

Hi to both Elco and Korneel

I am also planning to build a fully automated Herms-Setup. (Not sure if the valves should be automated)

Since i don’t have the required time to do experimentation i am waiting to see someone put together a complete build with schematics and parts-list.

I would like to buy most of the required parts BrewPi-Store, to ensure that i get it right.

Elco:

How far are you from publishing a build with, schematics and required-parts list?

Could it be an idea to create a “Complete Build” pre-filled shopping cart in your store?

Korneel:

Impressed with your work there ! Keep going strong, and appreciate your sharing

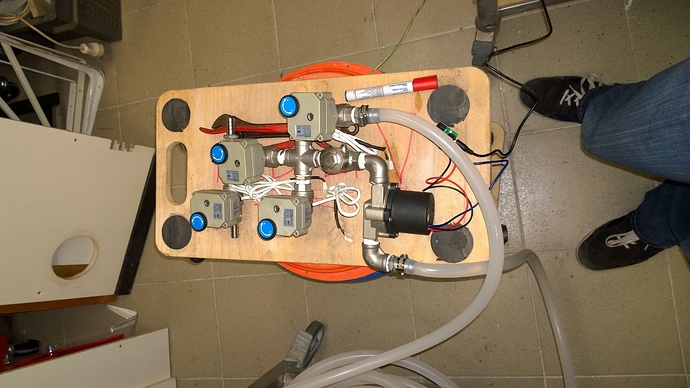

progress has been made

I’ve finished the cold water intake and the water cluster and the router portion. I’ve taken Elco’s deployment but i’ve added some flavor of my own by adding more temperature sensors. I figure that with the cost of the sensors, you can never have too many…

to be continued

did you complete the HERMS Build Guide ?

@korneel I don’t mean to sound like an asshole, but have you operated many brew systems with so many threaded connections before?

Those bad boys will be chock full of gunk before you know it and the cleaning is gonna be nasty! Anyway you can do wort control with butterfly valves and manage your water with autos?

Would that really be a problem if you follow up each brew day with a first a hot water and then a PWM cleaning cycle?

@Elco yep. Still a problem. What you describe is CIP and all the items used by most home brewers simply don’t meet CIP standards as most of us know.

This is fine, but you need to be prepared to pull the system apart to clean.

Pull apart your auto balls after 10 or so brews and let me know how happy you are to continue… As for all the threaded connections there are large shadows at each joint - great hiding spot.

I have no first hand experience with a full system of valves and threaded connections (just lots of experience with bits and pieces…) but I also worry about the manifold not draining after brewing… Do you get some nasty smelling stuff pushed out pre brewing sometimes?

Anyway… I worry about the movement in general of home brewers to auto valves… Much better off with a pro DME style manifold board and some TC’s… Or… Can you find us some TC autos Elco???

so don’t worry @cke11y  i don’t think you sound like an asshole and input is always appreciated!

i don’t think you sound like an asshole and input is always appreciated!

apologies for my late reply, next to my build i’m also doing a home renovation and that eats a lot of time

anyway i appreciate your concerns cke11y.

I think that whatever you are using, you will always have to pull it apart every now and then.

what i however believe in this case is that after your perform a brew, you fill the boil kettle with water, boil it, then slowly flush the system with this near-boiling water. as long as it’s over 70 degrees you should be able to at least melt and soak up most of the gunk. after a rinse with PWM and then another slow flush i think most of the junk should be out.

let’s say you don’t get it all, it would then get stuck in the filters… so i think we should be good… and taking it apart once a year is indeed something you would need to do.

@Elco and @cke11y

I did some research to your point about leaving gunk in the fittings and threads. i talked to a few guys that have been brewing for a long time and they quickly dismissed it as being an issue. if you use a CIP system that sterilizes the system, worst case scenario is that your filter has to catch some of that gunk or the color could be impacted. they also firmly believe that as long as you do a solid rinse after a PBW or Starsan cleanse you should be good. they actually stated they now try to build and keep their systems as much intact as possible. they do take apart all the things that they have touching the outside, such as the ball valves and hose couplings that get disonnected and connected during the brew.

i talked about the automated system and they told me (seperately) that they actually believe that you would not even have to clean the silicone tubing or the couplings as long as they are a part of the CIP. should they be taken apart because you are moving kettles then it’s a different story.

so i’m not too worried…

@korneel and @Elco It sounds like you guys are proposing the same cleaning regime that most home brewers do with their plate chiller right?

No different> boiling water > hot cleaner > Flush > Sanitise.

So… The home-brew movement away from these static plate chillers is because crap gets caught in them and affects the beer. Elco you have said that you worry about this! Next piece in the puzzle, is that within your automated valve/manifold assemblies you certainly will not get the VOLUME of crap that you get in a plate chiller… but otherwise whats different?

The one thought Ive had (and may be clear to you two and already on the radar) is backflushing a system like this with the exact same ‘CIP’ (in inverted comma’s since it is not CIP with threaded connections  ) may help significantly in the shadowed areas?

) may help significantly in the shadowed areas?

I think there is a difference between the static plate chillers (where there is intentional ribbing" ) and the “gaps” there exists in stainless steel tubing. I think one of the big differences there would be that the ribbing in the plate chiller is quite a bit sharper as compared to the smooth stainless steel portions.

yes, the backflushing is a great idea! i’m thinking of a way to do exactly that, to “soften” up the pieves with a slow flush with hot water, then a backflush with hot water at full speed… I’m thinking of building a seperate circuit for it or something like that, not quite sure yet

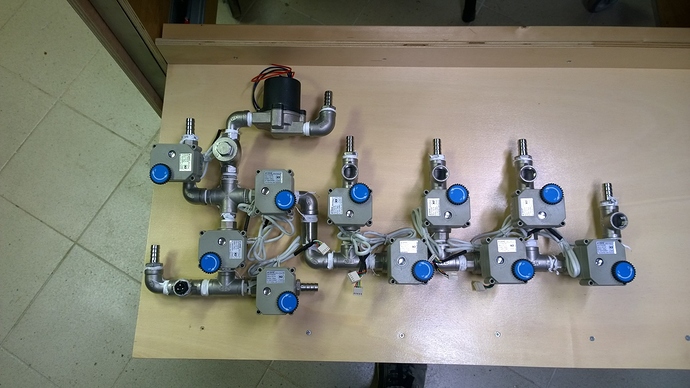

not sitting on my thumbs…

finishing the 3 clusters today and hooked them up, ready for a test run… unfortunately, one of the valve boards had a broken valve connection and I fried my photon… so no test run

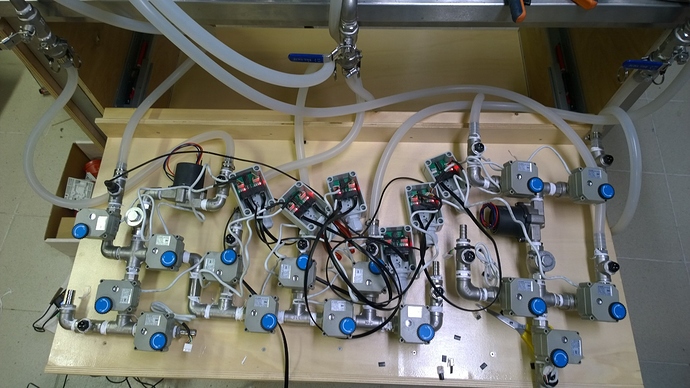

so, been quiet for a while… but stuff has sorta happened

first of all, i moved everything into my shed, i made sure the floor and walls are waterproof so i can spill, and i cleaned a lot of stuff up. also working on getting the control panel build, which is a big thing, getting power to the shed (3 phases) and clean water.

to do is finish building, getting a drain installed and getting a vent installed… so some pictures to proof I’m still busy

also thinking of getting 2 conicals so I can ferment 2 beers at the same time… difficult decision…

So I wanted to follow up with you guys @korneel @cke11y with the Brewpi Spark v3 and the Brewblox setup build. I Have a very similar setup to these pictures except I am using propane instead of electric for my heating but wanted to know if you guys have messed with the system and how you incorporated the electric ball valves and the relays for the individual equipment like the pumps, heater, etc. I currently got all my temp sensors registered/identified and labeled & now I’m trying to figure out the rest of it. Sorry for the N00b questions, but thank you for your time and assistance.

Korneel is using an prototype of our new ui that we manually linked to the old version of brewpi for the valves.

We are now porting that to Vue for brewblox and expect to have it ready in March.

Does your propane setup accept a PWM signal?

Let me answer it this way, I have it setup to where the transformer is activated by the relay based on temperature and where it is in the process of things. Here is a link based on what I’m doing.

Here is the relay board info:

https://images-na.ssl-images-amazon.com/images/I/91AHtk3PT3L.pdf

Input control signal voltage:

0V - 0.5Vdc, low level, relay not action.

2.5V - 24Vdc, high level, relay action.

Input control signal high level current:

2.5V: 0.1mA.

5V: 0.35mA.

12V: 1.1mA.

20V: 1.9mA.

and the transformer is a

Application:

24v Controls

VA Rating:

40

Voltage (Primary):

120v

Voltage (Secondary):

27 V.O.C.

Electrical Output:

24 Vac at 40 VA

Hertz:

60

Since this thread has been revived, @korneel any feedback on how has it gone with the cleaning the threaded connections?

I’m planning to move it a mostly automated build, and motorized ball valves are so much more affordable that sanitary or near sanitary alternatives.

Also curious if the check valves have presented any cleaning challenges. That’s what I was searching for when I stumbled on this thread.