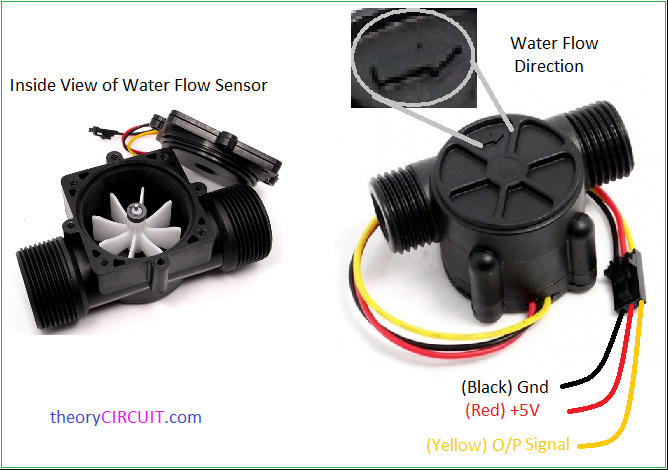

Here is a higher res version of the file from the post I referenced earlier. I agree and understand the pin out portion, and it is currently that way. Same power requirements and pin outs. Instead of wiring it directly to the RPI, based on the diagram and equipment requirements the Spark will be able to provide it natively.

Electrical Circuit - C.pdf (64.5 KB)

and

That flow meter is a simple pulse generator, for which you need to have an interrupt based microcontroller to listen to the pulses.

The BrewPi Spark will not support that. The way to support this would be to have an Arduino or similar small microcontroller act as a slave device with as only task to read this sensor and communicate with the Spark over RS-485.

The RS-485 communication has not been implemented yet, because all the expansion boards are currently OneWire. It was included in the hardware for future additions.

I will have to implement it soon for new IO modules, but currently the Spark has no way to add a sensor like this or even to talk to custom slave devices.

OK - no problem I do have an arduino lying around I can add too my setup - Ill have to research some more and ask questions about how to connect/wire it all together. I understand the software support part is pending, that is fine this isn’t a major item for the brew process to work, was a nice add-on.

Again, thank you so much for your time and support with such a huge endevour you have been able to support and take on - its quite impressive!

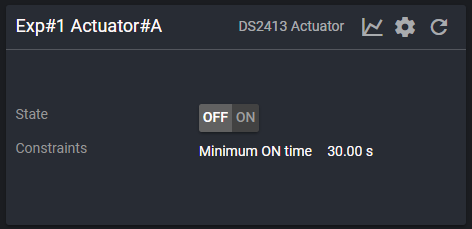

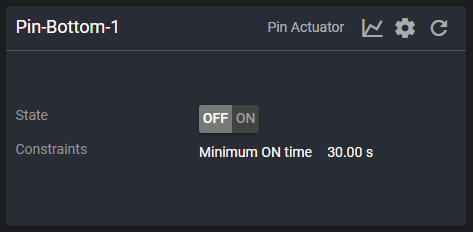

I now have all the expansion boards setup and labeled, in theory if I have a MIN time on and set it for XX - when I change the “State” from Off to On then the relay is activated and the device that it is connected too should turn on?

I just want to do a connectivity test for ea. of my outlets for the device they will be connected too. If this is or is not the correct process please let me know what I should have setup to have the same outcome. TIA

Also, is the process also the same for the “PIN” connections directly off of the spark for activating the relays?

Once this is tested, verified working, then I can move onto the ball valves when that support becomes available. Baby steps!

Yes you can toggle with that on off switch. I don’t understand why you think a minimum on time is necessary for this test.

it was just a value I had input - no logical reason really

thanks for the feedback / response very much appreciated.