Hello all!

I’m finally reaching the end of work on a plan I’ve wanted to realize for a long time–fermentation chambers that are integrated into a cabinet unit that looks nice enough it’s not restricted to the garage.

I’ve probably spent enough money on it that I could have bought a conical with glycol cooling, but doing it this way keeps my spouse happy and the owners association of the condominium I live in would probably frown upon me keeping industrial-looking equipment in the apartment. Building the cabinet unit itself was also a nice summer project with my father who is a woodworker.

The counter is a reclaimed table that had been sitting in my fathers basement. The cabinet is just plywood and beadboard with 1.5" foamboard insulating the interior and dividing it into three chambers–one of which is abutted by a repurposed mini-fridge. The chambers are lined with vinyl and caulked for easy cleanup. The front edge is sheet metal which magnets embedded in the doors stick to. There is a 1" hole drilled in the top of each chamber for wires and potentially a blow-off tube.

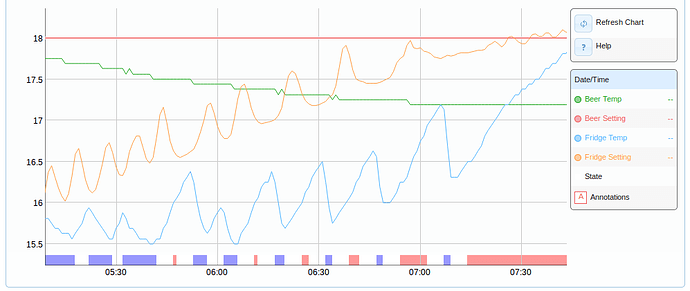

Cooling is done using 2 blower fans that blow cold air from the fridge compartment through ducts into the fermentation chambers. The ducts have cantilevered flaps on the ends so they are sealed when the fans aren’t blowing. There are return ducts (picture below) as well.

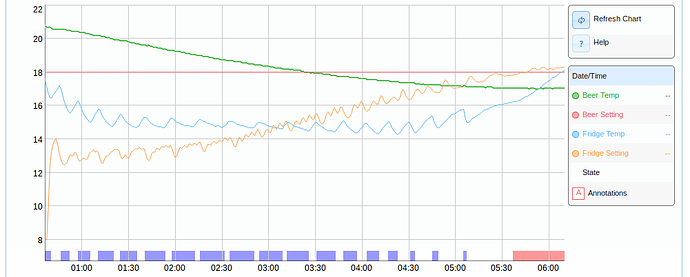

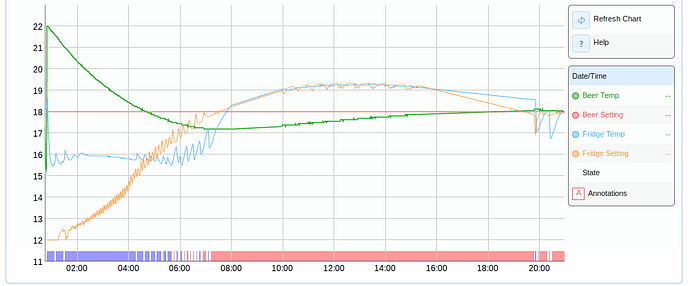

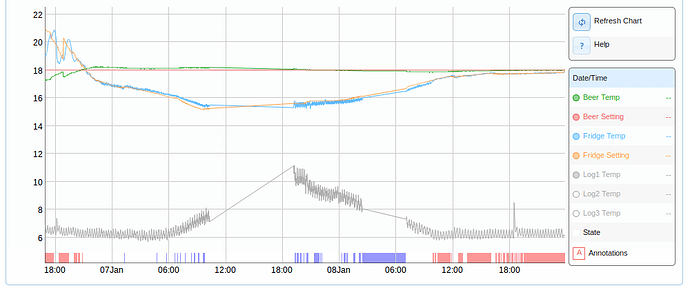

I’ve left the fridge alone with its original temperature control for now, although I probably will drop a temperature probe into that compartment for logging purposes. The cooling setup is a little spotty at the moment but it should become fairly efficient once the fridge-chamber is full of cold beer.

Heating is done via heating pads in each chamber. They seem to work fairly well. For now I have no circulation fans in the chambers.

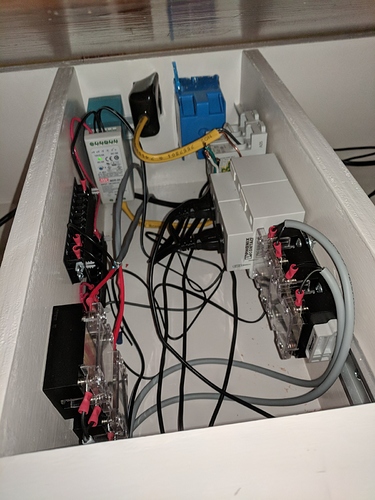

The unit has 120V AC and 12V DC circuits, with the a 5A DC power supply powering the blower fans, the Brewpi Spark, and potentially a stirplate as well. The heating pads and fridge run on the 120V AC mains power, and there is an outlet built into the back of the unit for easier access from the countertop.

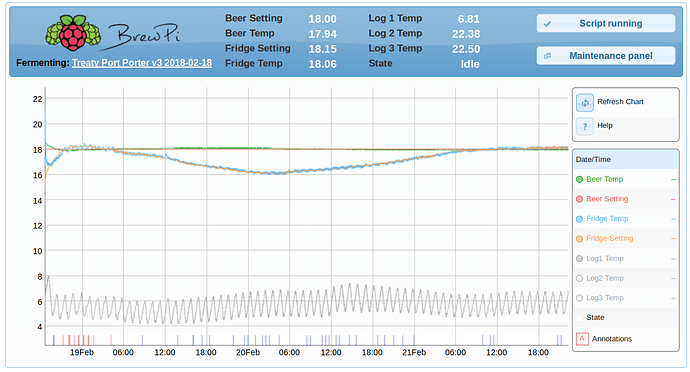

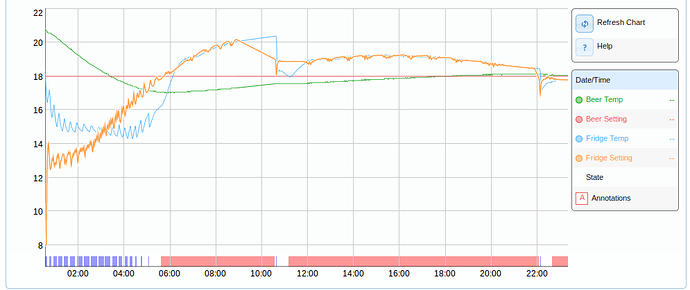

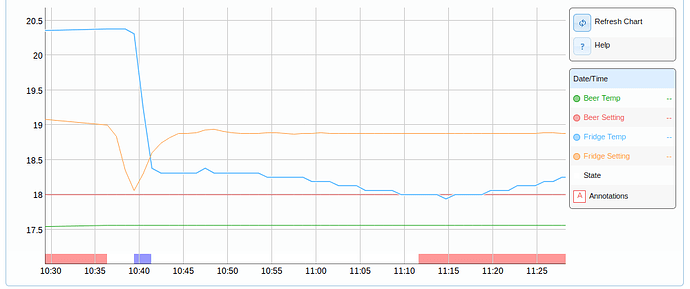

Even though I’ve finally got this project close to operational, I’m sure it will take some time to fine tune the PIDs and I would welcome any comments/suggestions from other brewers who’ve used brewpi with similar setups (fan forced cold air for cooling).

I’d also be happy to provide more pictures, details, parts lists, etc. if people are interested in the long journey behind the finished product.

Cheers!

Austin

. regardless, nice job!

. regardless, nice job! (although it does give me flexibility to keep things that don’t fit in a glycol belt temp controlled, like bottle conditioning beers)

(although it does give me flexibility to keep things that don’t fit in a glycol belt temp controlled, like bottle conditioning beers)