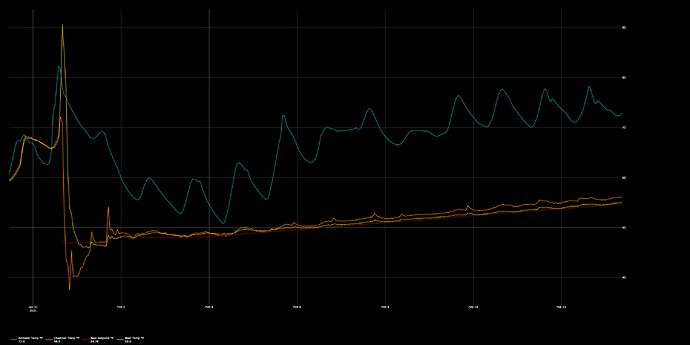

Just wanted to share my great experience using the default PID settings for my new set up.

New rig is a 21cu.ft. (very large) upright freezer that I have fitted to house my 18 gallon fermenter.

The freezer has a PWM fan that recirculates the air when the cooling system is running, as well as a temp sensor on the exterior to modify its cycle times depending on ambient temp.

Its a “garage-ready” unit, meaning it is designed to operate between ambient temperatures of 0degF and 110degF.

It has auto defrost as well.

Long story to say that I will be simply powering the unit up rather than taking discreet control of the compressor, fan, and defrost heater.

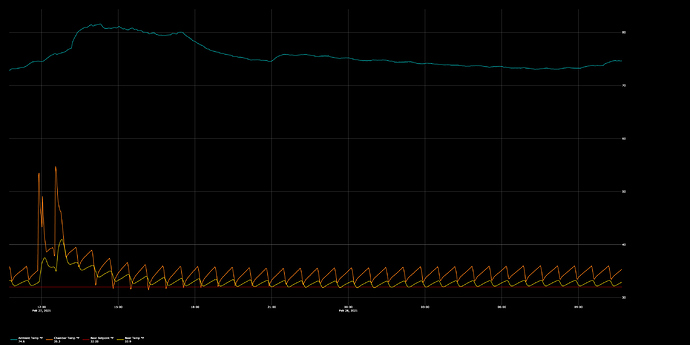

I have added a 65W ceramic heat bulb, for reptiles, and a 15W fan to blow when the heat is on.

I rarely have to use the heat, but last night was an example of “cold” temps around here; 55*F.

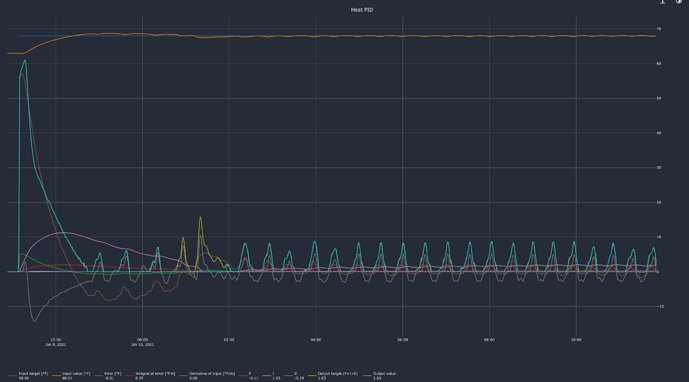

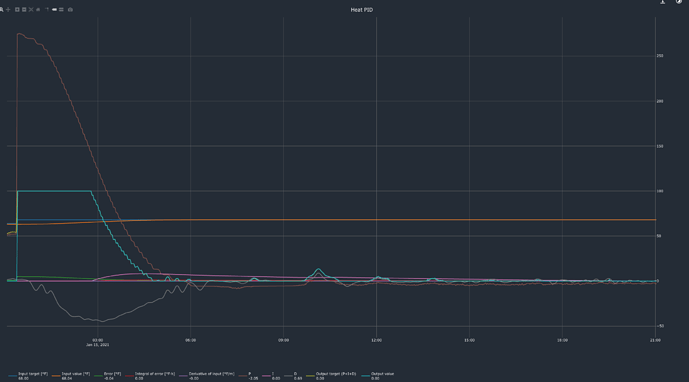

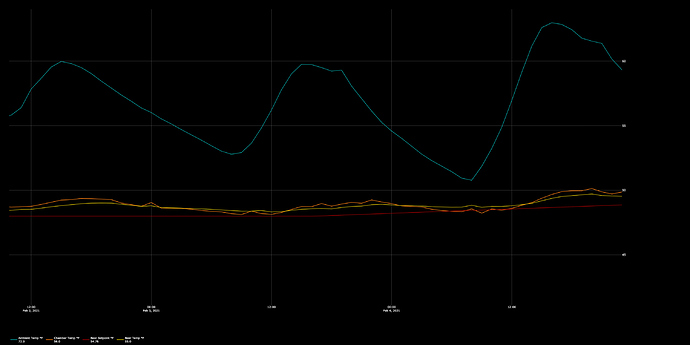

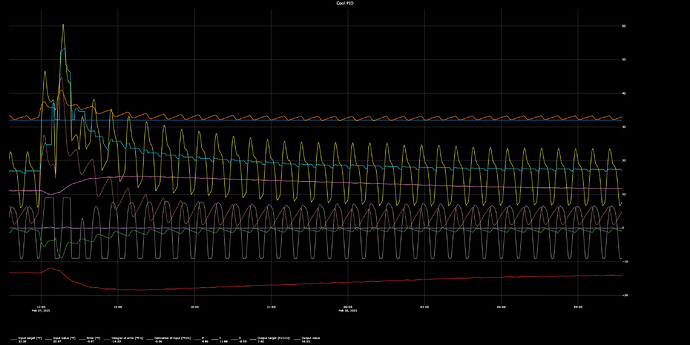

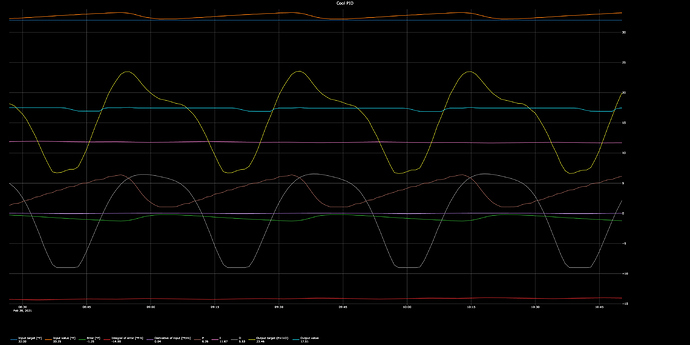

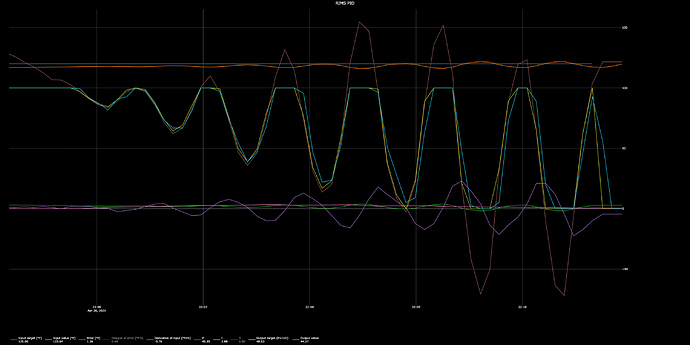

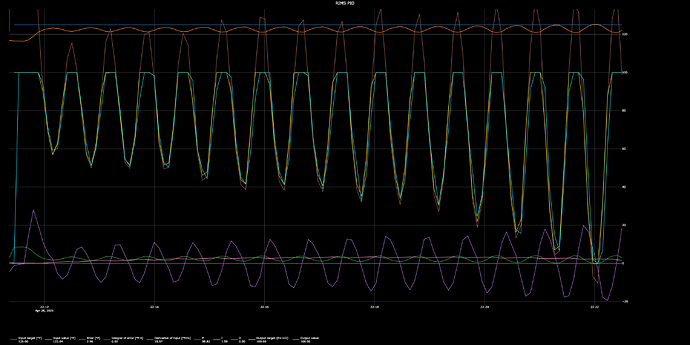

I took the opportunity to test out the recently updated default PID settings for fridge heat (Kp = 11.1*F, Ti = 2h, Td = 10m, PWM period = 10s). Worked out great!

The initial overshoot is only 0.75degF.

The subsequent undershoot is only 0.5degF.

The system settled into a +0.15degF, -0.15degF swing after about 12 hours.

That is ridiculously tight with no tuning required on my part!

Thanks for your continued development of this great product.

Now I’ve got 3 other modes to test before getting my first brew in…