Hello everyone! Could you please send me your settings for the Herms Coil with High Flow? I have a SS Brewtech Infusion MashTun 75 Liter, 24V PWM Pump from Brewpi. My system is still gassing, I have no liquid in 1 tube. Thank you very much

My recommendations:

- Don’t mill too fine. 1.2mm between rollers is what I use.

- After mashin in, don’t start pumping immediately. Let the bed settle first for 10 min.

- Try wet/damp milling.

- don’t start the pump at full speed.

I have tried with clean water so far. I can’t get air from the coil…

Where is the air entering the system? Are you priming the pump before you turn it on?

How is the pump oriented?

Do you have the false bottom in the mash tun? It will create a vortex and suck it air faster without it.

the liquid pumped through the coil does not push out the air that is there. one pipe is not a problem, three pipes at once is a problem.

I have never seen that happen, or I don’t understand what is happening.

How did you mount the coil? Do you have photos?

pump, valve, camlock are 1/2’'. However, the clamp adapter for the coil has a larger diameter, so the holes are partially covered, see the last picture- with the valve. In my opinion, this is a problem, why do I still have air in the system during mashing

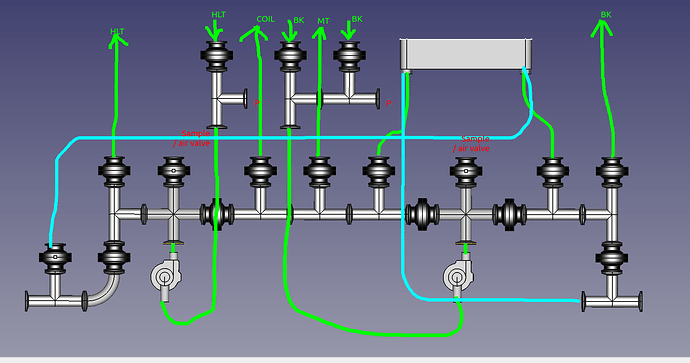

Here is an old photo of my brewery, but this part has not changed.

The mash pump is under that big sight glass.

I have no valve on the coil, just a high flow triclamp hose barb directly attached.

Why do you have a valve?

Above the pump is a valve to bleed air so the sight glass above the pump fills with water.

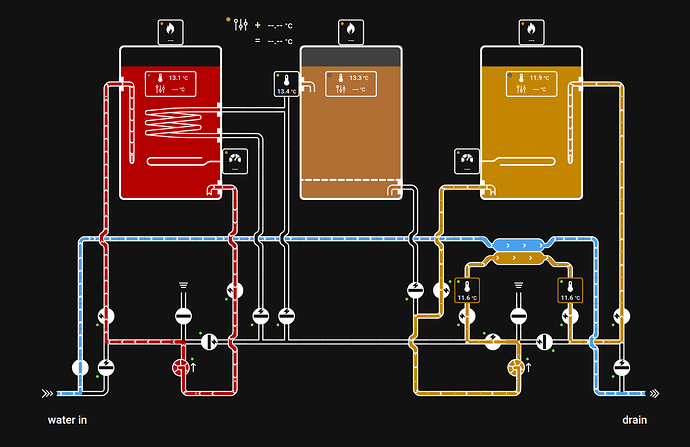

I am going to change my entire valve cluster soon to place the pumps at a lower position and oriented with the output pointing upwards, so it always will automatically purge the air.

This is my new plan:

Hi Elco. Thank you.

I still have a couple of questions regarding the connection between the pump, high flow COIL and upper valve on the infussion mash tun.

Elco: I have no valve on the coil, just a high flow triclamp hose barb directly attached.

// you have a valve on the coil - it’s actually the valve you have in the picture on the infusion mash tun in the upper part.

Do you use it to regulate the flow during circulation? in what position is it when you turn on the pump at the beginning of recirculation?

what do you mean by “high flow triclamp hose barb”? what is its diameter? can I buy it from you?

I have pneumatische valves, they are only fully open or fully closed.

Why would you use a valve to pinch the flow when you have a pump with speed control?

This is the high flow barb: Tri-Clamp 50.5mm to hose barb adapter (1/2" ID) - Tri-clamp Fittings - Mashing

I use Camlock Adapter Tri-Clamp. It has an inner diameter of 15mm, which is more than your hose barb clamp adapter. Even so, the connection to the coil is exposed, see photo. each of the 3 tubes is covered by an adapter for approx. 30%… this can cause problems with optimal fluid transport.

The biggest problem is the valve. Use the pump speed control to regulate the flow with a fastpwm block, don’t block the flow with the valve.

And I assume you have mash tun out → pump → coil → mash tun in.

then what is the point of using the upper magnetic valve in the mash tun pot in your brewery?

I don’t have a valve. I have a temp sensor at the inlet, just for measuring, not for control.

ok, thank you. I will try it without the valve at the end. at what approximate speed (liter per minute) do you start recirculation (standard malt pale ale grind to 1.2mm, 4 liter water pro 1 kg malt… )?

Just start low with the pwm at for example 35-40%. I don’t now how many liters per minute that is. Slowly increase once the flow gets easier.

Don’t pump immediately after adding the grain.