Are you planning on doing the coils on the side?

Yeah, the Brew Master Edition comes with the coils. I’ve got the same one, but didn’t go all out and get the shelf, leg extensions AND casters. WOWZA! That’s nice.

Ahh very nice I haven’t looked at this series much since I got mine so long ago.

they are incredibly nice…

not just the butterfly valves, but also the heating pad, you can almost directly shove the new temp sensors in, the build in cooling spiral…

i also odered the leg extensions, wheels and stainless steel shelve… they are awesome…

Expecting mine on Friday. I hope the heating-pad from the FTS kit can be used in combo with a brewpi.

Multiple-loops support is going to be very used as I will need it now for both mashing and fermenting…

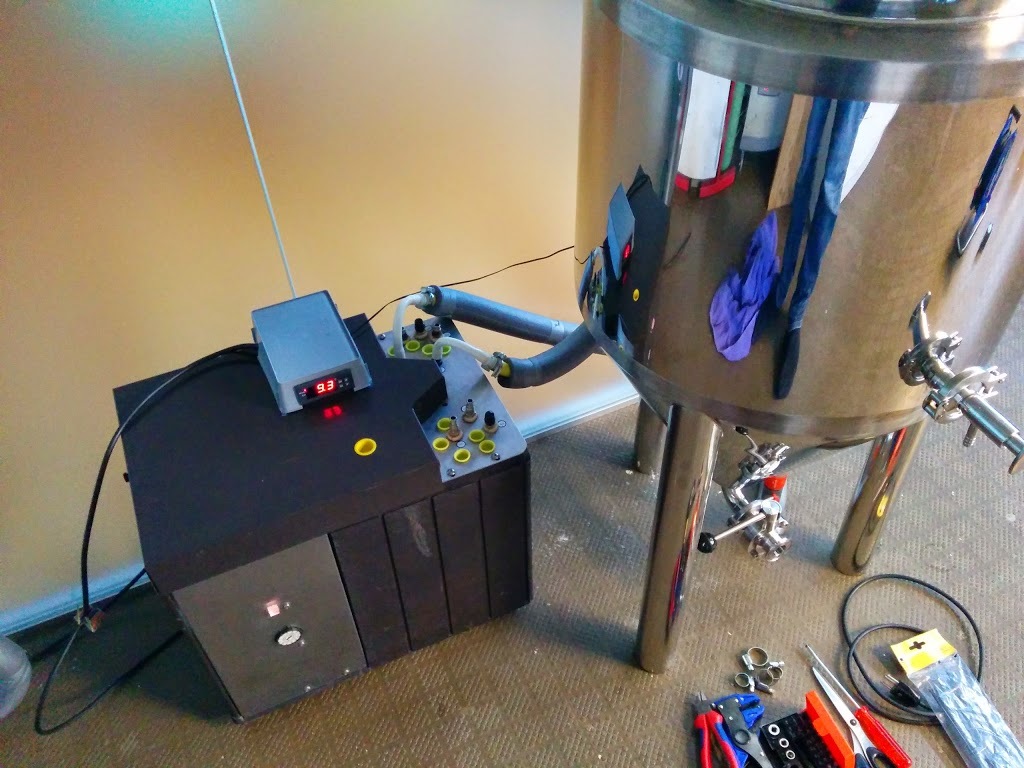

I got 3 new 150 liter conicals comming in next weekend from china. The isolation and cooling jacket are built in, the are pressure resistandtto 3 bar and got CIP cleaning:

I am wishfully waiting for the glycol-setup-update, and especially multichamber-support-update.

China  It is the second time I ordered from the supplier. Before I publish the contact I want to wait until I see the quality of the welds and so on. After having seen the first conical there were some serious issues which need to be adressed. I really don’t want to make anybody order a tank from a supplier I recomended with minor quality.

It is the second time I ordered from the supplier. Before I publish the contact I want to wait until I see the quality of the welds and so on. After having seen the first conical there were some serious issues which need to be adressed. I really don’t want to make anybody order a tank from a supplier I recomended with minor quality.

I will let you know as soon as they have arrived.

can i ask how much you paid for tank including shipping (and including destination?)

If you want to find a good list of pro gear you should check out the forums on probrewer.com and the BA forums. Both sites have a wealth of information on suppliers and much much more.

Cheers,

-Stephen

Finished assembly of mine (1BBL model). Hopefully, there will be a way to drive the pump for the cooling-coil and the heating-pad from Brewpi.

I began building my glycol chiller yesterday. I’m really happy with it. It’s a 2.9kw portable unit - my electrical engineer friend will help me bypass the control board this weekend so it’s ready for a temp controller to maintain glycol temp. The brewpi would do a much better job of this so I’m excited for this future possibility. My brewpi is a dedicated brew day unit at the moment so I’m thinking despite future multi chamber abilities, I might need a second unit to control this glycol chiller. Particularly since I want it to be a little mobile.

I tested my unit without liquid yesterday and I brought the air temp in the cooler from 23 to 0 in 9 minutes!!!

Those running air con based chillers- have you done anything about coil rusting? Painted your coils or anything? Also, has anyone bothered removing some fins to improve coil contact with the liquid?

@Elco do you think there is any merit in adding some neat kind of interconnectivity of some description for those people with 2 Brewpi’s? Not sure what exactly… I’m just thinking out loud.

And @chixxi I totally understand not mentioning suppliers yet, but please please please let us know where you got these from if you are happy on arrival. I would love to have a few of those in order to use as a bright tank and serving tank for big events at home.

Holy shit that’s a heavy duty glycol chiller.

How big are your fermenters?

I am just going with a 10L glyclol tank inside my keezer (which is 700W itself). My conical is only 50L though. Wonder what would warrant such a heavy chiller.

So … A few things…

-

Freezers can’t remove heat quickly so the amount you can cool from ambient is pretty small. I’ve had a 30L reservoir of salted water in a freezer set at -5 for quite a while, and in Australian heat I struggle to maintain anything less than 17. This is fine, but I want to crash chill. I’ll be interested to see how you go with your setup. The thing I did with mine is had a copper coil submerged in a solid block of ice in the freezer on the return line. This means that returning liquid got an extra cool down before hitting the reservoir.

-

I will run 2 X ss 14 gal fermenters off this. Or something with a jacket if I can find it - I have the aftermarket drop in coils and don’t like them very much - I’m keen to see the coil like yours in the flesh. I just think jackets are safer.

-

I had this large cooler spare from my wedding, and the air con was $50 from a neighbour!

-

I have a mobile canning rig on order and for commissioning and testing purposes I really need to be able to hold my own beer at 2 degrees or a little less in my future bright tank.

Edit, I think my conicals are bigger than 14 gal. Why the hell am I talking in gallons anyway! Mine are 60L

My plan is to mount this fan and heatsink:

http://gelidsolutions.com/products/index.php?lid=2&cid=12&id=80

On the side of this:

Using thermal glue. Then I’ll place it in the freezer, next to my kegs.

The freezer I have is a Haagendaz glass door ice cream freezer. You’ll see photos of it soon.

I’ll post on the blog when it is done.

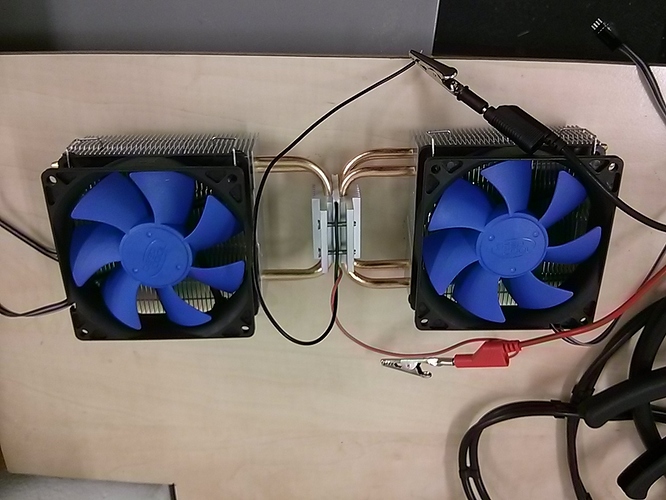

I had the following setup in a freezer at -20 celsius and it was by far not powerfull enough to get my 80L conical below +20 Celsius. Not even mounting a fan helped a lot:

I am now using flow through chillers which are normaly used for cooling beer on tabs:

The power of the freezer should be plenty, it is mainly about increasing the efficiency between freezer air and glycol.

I hope my stainless container is better at conducting heat.

If it is not sufficient, I think I’ll sandwhich 2 CPU cooler around the lid, similar the the photo below. Wall in place of the peltier, no fan on the glycol side. Note: I don’t recommend peltier.

I didn’t paint mine for the following reasons:

- I was worried about heat transfer with paint on it, albeit possibly minor, it would reduce transfer.

- My buddy has had his setup going for 3+ years and hasn’t changed a thing, it works fine.

- At 3+ years of life, the ~$50 it costs off Craigslist to buy a new one seems pretty reasonable.

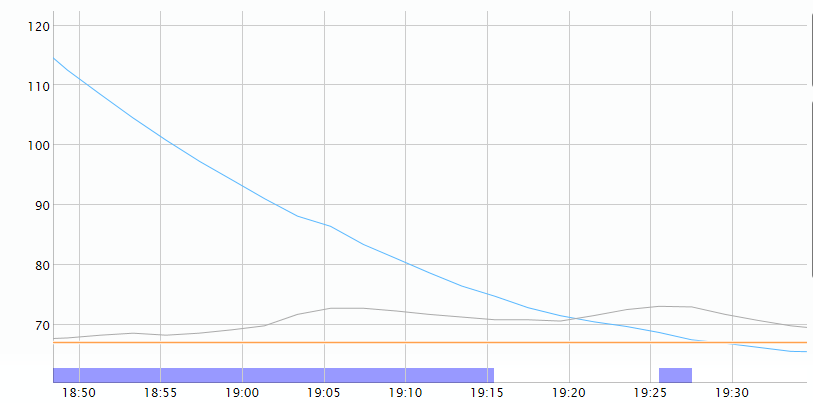

This last weekend I did an extract kit I got from Norther Brewer for free, so instead of my normal pumping through a plate chiller directly to a cam lock at the bottom of the fermenter, I recirculated until it got to 130, then dumped it in the top of the fermenter (with a fixed 5g volume, I didn’t want to lose any to the 25 feet of tubing it takes to go from my brew stand to my fermenter room.)

It dropped from 130F (the graph shows only 117 because the filtering function of BrewPi hadn’t caught up to real temp before I let the pump Rock n’ Roll.) to 67F in 40 minutes. That’s 1.57F or 0.88C per minute.

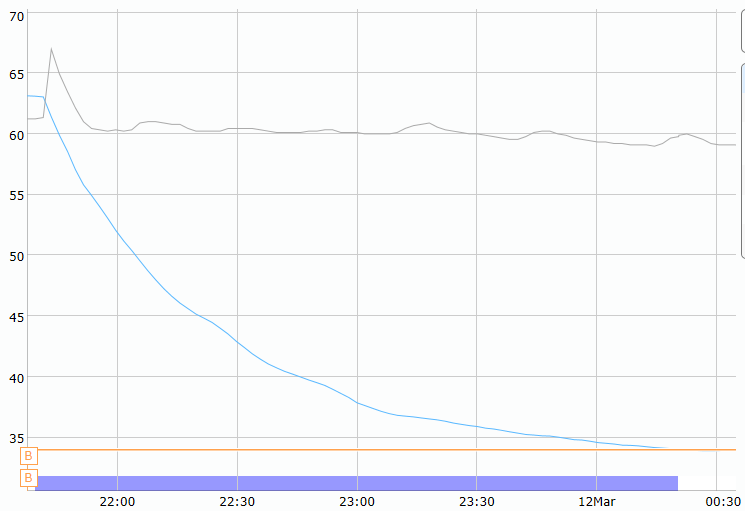

Here’s a cold crash I did on 13g of beer (63F to 34F in 41minutes) this used to take 3 days to achieve in my fridge:

I have two BrewPis on mine because I couldn’t wait for multi ferment capability. I did a hybrid of letting it auto-install and following the instructions for multiple BrewPis on Elco’s site. The only real change I made was using symbolic links so the two different webpage locations share a graph log directory; I don’t want to have to remember which fermenter had which beer in it when I go back to review my “Previous Beers.”

Also, BrewPi doesn’t handle glycol very well without a lot of parameter changes, (as it wasn’t intended to, but now that @Elco has a SSBrew Tech and glycol coming, I have a sneaking suspicion the native support will become quite good;) 2m of cooling time would drop my beer WAYYY to far down, the initial testing spikes were huge, but now I’ve got it down to 0.3*F variation which isn’t as good as using a fridge, but darn close and now I’ve freed up my fermentation fridge to be a lagering fridge!

@Elco I did a lot of research about people using Freezers of any sort to try and have a go at glycol and I didn’t read very positive reviews; they basically had performance no better than just sticking it in their Fridge. That’s why I went with the same setup as @cke11y although mine is only a 5,000 BTU window unit that runs about 1kw of power.

To simulate a body of water in a freezer with air as a transfer medium I did a test putting the condenser in the cooler, but not IN the glycol and it struggled to maintain temp on both fermenters. I wish I had had BrewPi log it so I could show those graphs. A watt or BTU does not result in the same performance in air as with the condenser submerged. I’m not trying to insult your intelligence by saying you don’t realize this, because it’s obvious you do based on trying to add heat sinks and fans to increase the performance, but I was blown away with the performance difference; 6 gallons of glycol went from 65F to 20F in 15 minutes with the condenser in glycol.

Try this:

Use 0.4.3 beta. Run with only a beer sensor. The input for the cooler will automatically fall back on the beer sensor with no fridge sensor available.

Set the cooler PWM period to for example 4 minutes. Set the minimum ON time to only 10 seconds. Same for minimum OFF time.

Then adjust Kp like this: if you think with 1 degree difference, the pump should be on for 10%, set Kp to 10.

Ti: how long should it take to adjust steady state errors? I think 30 minutes is reasonable: Ti = 1800.

Td: how far ahead should the PID look to prevent overshoot? If the pump turns off now, how much longer will the temperature drop? This is Td, in seconds.