Hi all,

I had my first brew day on my new system yesterday! It went great (except for some problems that had nothing to do with brewblox). I had one follow-up question though regarding PWM control for the boiling kettle.

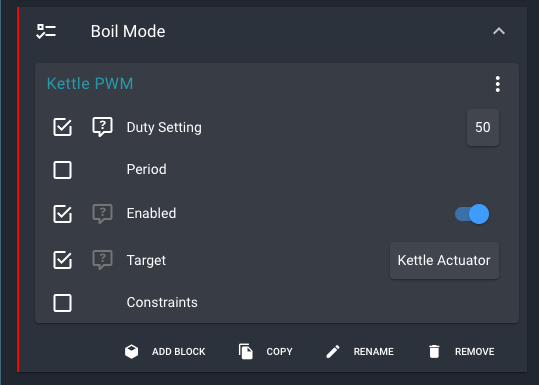

My temperature sensor for my kettle is mounted in the plumbing (in a tee between the kettle and the outflow valve). As such, I can only get an accurate temperature reading when the pump is running. Not a problem for mashing and chilling, but I wasn’t able to control the intensity of the boil without keeping the pump on, and I do not like to have my pump running during the boil as it is unnecessary and puts too much stress on the pump and tubing. So the reading on the kettle sensor fell quite a bit below boiling temperature with the pump off, and the PID was outputting 100% as a result. This wasn’t a huge problem either, except it is also unnecessary. My boil was so vigorous that I managed to boil-off around 12L of wort in 90 minutes. If I had been doing a larger batch, however, I’m worried that this intense of a boil would cause a boil-over, or at the very least a lot of splashing for the first 30 minutes. My question is this: can I easily set the Kettle PWM to 50% (for example) during the boil? I’ve created a quick action in my profile here but haven’t tested it yet. Is this sufficient or is there something I’m missing?