Hi all,

A question on how to dial in my PID, after temperature is less stable than with the previous release.

I’ve set up brewpi (with spark) on the latest release past Saturday. I was especially grateful to see that latest errors were taken care of, such as reported in the ‘brewpi froze my beer’ topics – I have had similar under/overshoots and a pause in functioning.

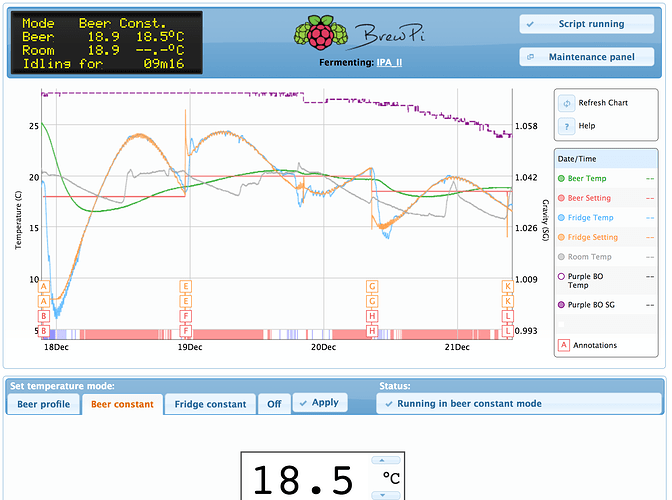

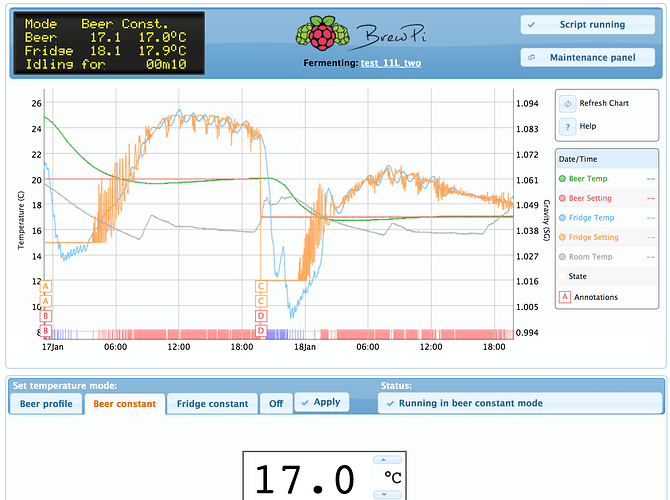

I’ve started a brew past saturday, in beer-constant mode (18degC). Pitching temp may have been too high (though similar temp hydrated yeast slurry and wort), but I think the undershoot (-1.5degC) caused the yeast to stall. After repitching fresh yeast two days later, it’s underway now, but with +/-0.5degC variability, and this used to be less.

How can I adapt the settings?

My setup: 15L glass fermenting vessle with beer probe in a thermowell, latest raspberry NOOBS release, latest brewpi & spark releases (0.4.4 stable), tilt release of last week (not the update of 3-4 days ago). All settings default - or am I overlooking something?

Beer-to-fridge Kp=2, Ti=7200, Td=1200, max diff=10, input delay = 18sec, filter delay = 159,

Cooler Kp=10, Ti=1800, Td=200, PWM=1200, min off = 180, min on=120, input delay = 18, filter delay = 159

Heater1 Kp=10, Ti=600, Td=60, PWM=4, input delay=18, filter delay=159

Heater2 is reported in settings but I am using none.

Dead time = 1800

Edit: I’ve seen that the beer-to-fridge settings may be changed, but to what extent? Eg:

- b2f Td from 1200 to 2400?

- b2f max dif from 10 to 5?

- b2f filter delay from 159 to 300?

Or should I tweak the settings separately for heating/cooling?

Thanks for your effort and help!