Anyone have recommendations for starting settings for a 15 gallon stainless steel, glycol dimple jacketed and insulated conical fermenter? I was using the spike before with the chilling loop, and I could never get it to hold a consistent low temp for cold crash, so tomorrow will be my first batch with a new Brewers Hardware unit. I would bet the temp responds much faster to cooling now, since it’s a full jacket and much better insulated, but I don’t know where to start.

I have chilled glycol from a trunk line glycol chiller (same as the SS brew tech 3/8hp one, but I have the bigger pump, for a 60 foot trunk line, not the little dc aquarium pump.

I have had good results with the following settings:

- PWM period of 10 minutes

- Minimum cool time of 10 seconds

- Kp of 10, so the pump will be on 10% when the beer is 10 degrees too low

What about Ti and the Derivitive and any filtering?

Set Ti to 2 hours and start with Td at zero. The filtering depends on how noisy the measurement is, try 5min.

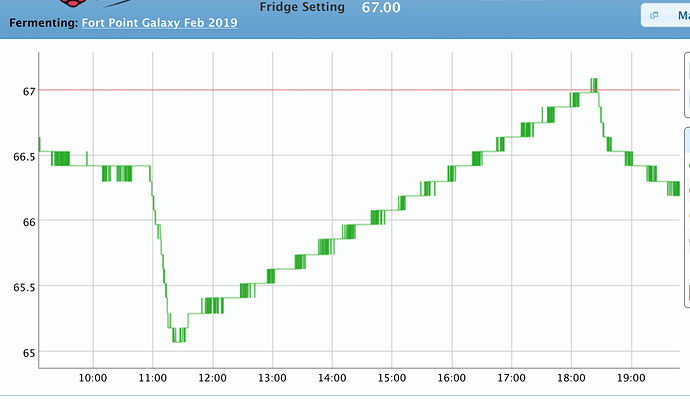

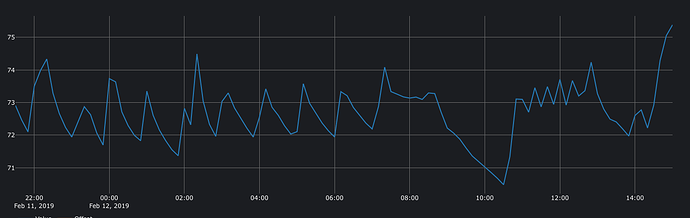

Ok, I started there, and the cooling jacket has way more power than I expected. Check out my graphs and let me know what you think:

Zoomed out:

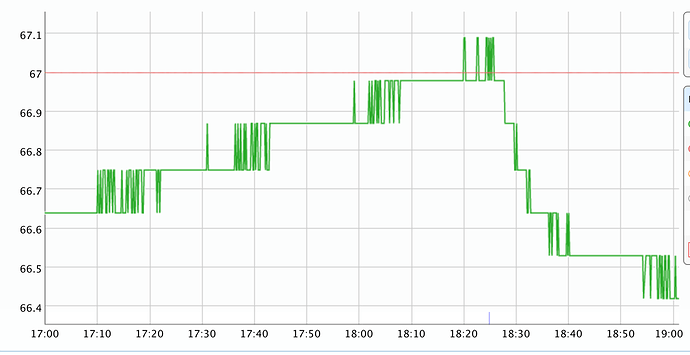

Whoa… why did that dip if you can’t even see it cooling??:

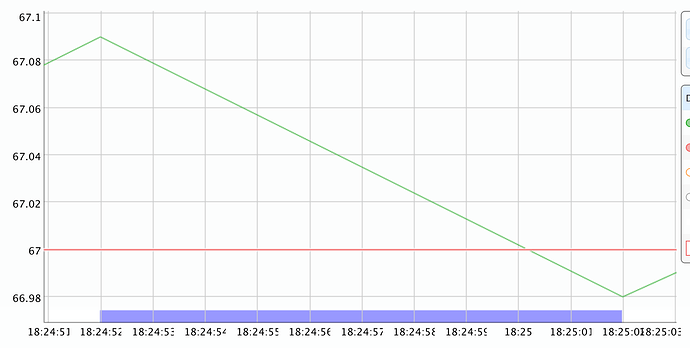

clicky click enhance… click click click enhance… keyboard noises enhance…

so 10 seconds of cooling brought the temp down over the course of an hour and a half, to .8 deg under my setpoint. I know that’s a small difference, but any suggestion on what I could adjust so that cooling is used sparsely, and to let the temp rise to say… .5 deg F above the setpoint before the pump is turned on, so it kind of bumps up and down across the setpoint? instead of just barely getting above it?

Wow, that’s a big drop. Perhaps because 10 seconds refreshed the water in your jacket and that still water cooled the beer over the next hour.

Any idea of the volume of water in the jacket?

You’ll definitely not want the minimum cool time of 10 seconds and you’ll want very short burst with a long period in between.

Example:

- PWM period of 10 minutes

- Kp at 0.5

- Temperature error of 2 degrees

will give you 2 * 0.5 = 1% ON. 1% of 10 minutes is 6 seconds.

I saw you installed BrewBlox in another post. Please note that in BrewBlox coolers need a negative Kp.

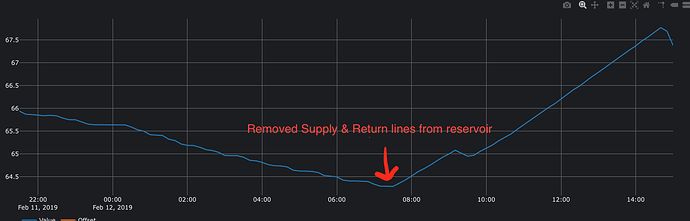

I think the jacket holds a maybe 3-4 liters, I’m not sure but I had to refill my reservoir after I plumbed it in, so it’s substantial. I actually think once the pump kicks on then off, I’ve got free convection current in the system, which is causing that sustained drop, because it kept dropping all night until I popped the supply & return out of the liquid reservoir. The jacket is plumbed with the cold supply entering the bottom and return at the top, and then my chiller is mounted above the fermenter on a shelf, and I think the warming glycol rising up to the tank was enough to start a current. I’m waiting on an electronically actuated ball valve to arrive, so I’ll close the line when the pump is off.

I know you’re probably full out fixing bugs and getting ready for release, and I may do this if I get some spare time, but it would be nice to have an actuator delay, so I can open the ball valve and then start the pump a couple seconds later, to give it a soft start.

I was looking at just putting in a pressure relief valve in the manifold, but they are ridiculously expensive, McMaster has this for 70$ https://www.mcmaster.com/9763k11

That feature has already been requested by another brewer on glycol. Will add such an actuator :).

If your glycol lines from and to the reservoir are a closed loop, I would be very surprised if it continued to flow after shutting off the pump. Maybe reversing the direction would help.

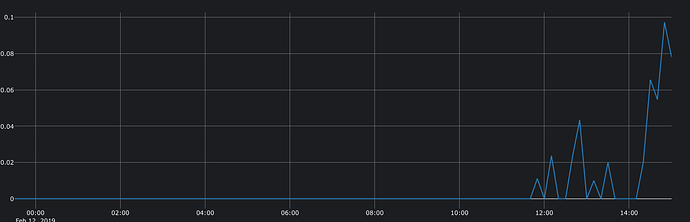

It’s not exactly a closed loop, and fluid can flow through the pump when it’s not running, I checked. This is my guess from looking at these graphs:

Beer Temp after switching to BrewBlox (after I made this post, I wanted the PID graphing)

Ambient Temp outside the electrical box, during the same period:

Pump Duty Cycle during the same period:

The pump wasn’t on, the ambient temp was fairly consistently 8 deg warmer in the room, and this is during primary fermentation on a fairly good sized beer, it should be demanding a lot more cooling, not consistently dropping temp. Then when I pulled the supply and return lines out of the glycol bath, it starts to raise… what else could it be?

I’d like to have a closer look on your charts and settings.

I can invite you to slack or Skype.

slack would be great.