Ok, to prevent overshoot, make sure your beer-to-fridge Kp is set to mash volume divided by HLT volume.

OK it now looks like I need two systems, one for fermentation and one for brewing as I cannot shut down fermentation to brew. So is the original Brewpi (RaspberryPi) sill usable , with its current downloads for fermentation? If this is true I can remove the one wire SSR interfaces and restore the original set up that worked beautifully and redo the config files for fermentation only set up. I will also need to re-evaluate what I do to my old Brewtroller DX2 system controller that died. I have not brewed in a year and need to start brewing by June even if I convert my controller to manual only, so I will be looking at my options between now and then regardless of financial impacts of all the Brewpi Spark harware purchased to update my brewing system.

Thank you and good luck Elco.

Mike

Hi Mike,

The current version works for mashing and for fermentation, just not at the same time.

We are working on this, but it requires a lot of changes and it not ready yet.

I’ll also reply to your e-mail with further suggestions on how I can help out bridge the gap until our software is ready.

Elco

I’m losing my mind. I’ve spent all day ensuring that I had good power, cabling, and network connection. I can’t get the brewpi to let me assign more than 3 temperature sensors and no more than one pwm output. Setup is as follows:

Sensors: HLT output, HERMS output, MT output, chiller output.

SSRs: HLT element and BK element.

Mash control works fine but I can’t get the system to let me add the BK SSR in to control boil-off or the chiller sensor to log cold break efficacy.

What am I doing wrong here?

You are not doing it wrong. In the current version, it is not possible to have more than 3 temp sensors and a heater and a cooler. We are rewriting the software from scratch to have a fully configurable setup with almost unlimited sensors, actuators and PIDs.

Ah, I see. So in it’s current form it would only work to control boiler duty cycle in a BIAB setup. I have an SSR with built-in PWM that uses a 500 ohm variable resistor for control. I’ll just put that in for now.

Two questions:

-

I use thermopot with insulation and cover. The loss of heat is minimal. I have always overheating because the temperature in the HLT is much higher that MT.

Which parameter can best be regulated? I think lowering the maximum difference between the fridge and beer. -

I use the Brewpi resistor of 5500W. It’s normal that in PWM mode the light continues to pulse? The system does not adjust the power of the resistance decreasing consumption? Here, however, continues to turn off and turn on when close to the set point

- Decrease beer-to-fridge Kp, increase Td. You can also decrease the max difference indeed.

- It pulses to decrease the power. With such high currents, it is inefficient and simply impossible to increase the resistance to lower the current. You would be generating kilowatts of heat outside of your kettle.

Hi Elco.

Using my Brewpi just for fermentation now, but are looking into building a new 4 ketle HERMS setup.

Not yet desided if I’am going for a Kal-clone setup with regular PID’s or a BrewPi based system.

But as I am going for 4 ketles, my system need to support 3 heating elements, and two of them need to be controlled

at the same time.

- HLT (50 or 80 liter vessel, will prepare strike and sparge water) 3500W or 5500W.

- HEX ( A small vessel for controlling the mash prosess- 4-5 liters) with a 2500W element.

3.MLT (no heating, just temp probe(s). - BT (100l Boil ketle will be 2x3500W or a 5500W)

So I need to be able to controll both the HLT and the HEX as two seperate prosesses at the same time.

When switching to boil, I’ll probably do a manually PID/PWM anyway.

Also, a GUI that reflects mashing system rather than fermentation would be nice.

Is this something you see ready in the near future ?

If so, a second set of Brewpi would be purchased as I am

very pleased with my fermentation chamber.

Cheers.

Hi TomA,

We are rewriting the software to make it possible to adapt it easily to various setups.

The new software is in its early stages, so I do expect that it will take until the end of the year before we have something really usable.

Cheers

Hi

are awaiting shipment of my Brewpi Spark and misc. fittings. While i wait. i have a few questions regarding using the Brewpi in a HERMS setup:

I plan on measuring temp on the wort as it goes into the HLT through the herms coil, but no measurement of wort going into the MT. is that good enough ?

Is there a “how-to” on setting up the Brewpi for mashing with the current fermentation GUI ?

With a KAL clone (Electric brewery) it is possible to have an alarm going off when temperatures are reached. Can this be done with the Brewpi ?

Description of my setup

3 kettles each 117 liters (SS Brewtech)

Heating elements in HLT and BK

Herms coil in the HLT.

How do I :

Control the heating element in the HLT for warming up strike water ?

Control the heating element in the HLT during mashing ?

Sorry about all the questions, but I have been brewing with gas for so many years and electric brewing is a complete unchartered territory for me.

With my setup, the HLT will be about 4 degrees above the mash tun output.

This will also result in a temperature distribution in the mash tun: HLT temp on top, 4 degree lower temp on the bottom, and 2 degree lower temp in the middle. Better mash tun isolation will help.

I helped a friend brew yesterday with an SS brewtech mash tun and for him the difference was only 1 degree.

I would measure the mash temp at the output of the mash tun or in the middle of the mash tun.

What I do is heat up strike water in the boil kettle (full power, as manual actuator). I have the room temp sensor assigned to the boil kettle to keep an eye on the temp.

I pre-heat the HLT to the 4 degrees above mash temp that I expect to need.

After striking in at 72 degrees, the resulting temp will be 65 degrees, due to the temp losses to the grain. I give the grain bed 10 min to settle before starting to pump through the HLT (kept at 68 in fridge constant mode). I then switch to beer mode at 65 to automatically manage the HLT setpoint.

Im sure its covered elsewhere, but any news on herms interface for the webserver?

@Elco, I modified Brewpi Arduino based to control my mash. The only thing I did was remove compressor time protection. Do you imagine the the rules posted in the very top of post will be the same for me? I have lag time, but I think it is impossible to modify.

MT normally with 32,5L

HLT normally with 44,0 L.

Herms with chugger pump and false bottom.

Thanks,

Fabiano da Mata

No, the arduino version of BrewPi is very different and not very suitable for mashing.

PWM was added for the spark version, but not for the Arduino version. The Arduino version also has overshoot detection implemented very differently. The control algorithms have been completely redesigned, partly to make them more suitable for mashing.

Hello Elco,

I haven’t been brewing for a while and ran into an issue with my Raspberry PI, which seems having damaged the SD card (stopped loading) used to control fridge temperature through the old BrewPI Spark. Where do I find the installation guide for the previous BrewPi fermenting software use to control the temperature.

BR Ken

We don’t support the old BrewPi software anymore. We discontinued it years ago and transitioned everyone to Brewblox, which we still actively develop and support.

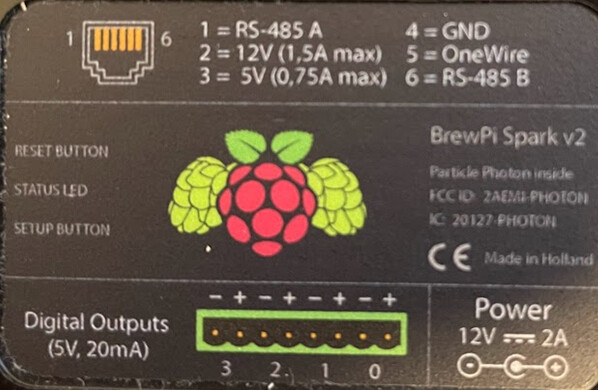

Did you ever replace the Particle Spark Core in your Spark 2 with a Particle Photon?

We support Brewblox on the Photon, but not on the older Spark Core due to hardware limitations.

We still support the Spark 2 when it has a Photon inside, and with Brewblox you’ll get all the new features and better control. I don’t know if it is still possible to buy a Particle Photon v1, because by now that has been discontinued too (but still supported by us as long as we can).

Hei Elco,

My Brewpi Spart is v2 including the Particle Photon.Below is af photo of the backplane which might tell you everything and whether it will work with BrewBlox.

BR Ken

Right! My mistake! The Spark 1 had a Spark Core, the Spark 2 always had a photon.

Then your hardware is fully compatible with Brewblox!

You can follow the guide here:

What is the version of your Raspberry Pi?

Hi Elco

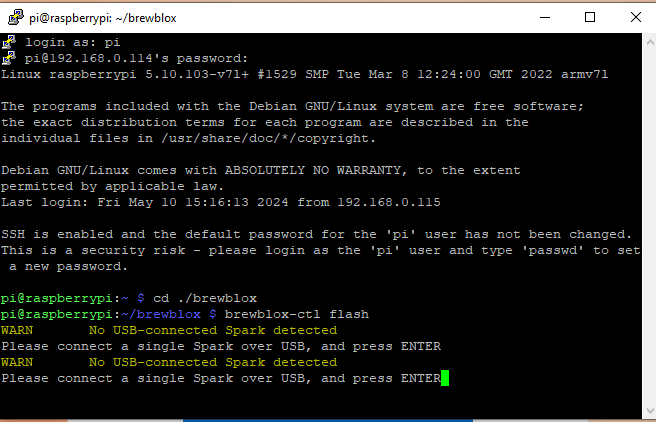

BrewBlox say No Spark is connected through USB when trying to flash, even though my Spark is connected. Does this have to do with the Photon configuration?

BR Ken