I have been testing the new version of BrewPi a lot on my HERMS setup.

The new controller code has been tweaked a lot to work well when controlling mash temperatures.

The user interface is still very much fermentation oriented, but by changing a few settings, it will work well when mashing.

There are 2 options:

- Controlling a heater directly, based on your mash sensor

- Cascaded control: your HLT setpoint is adjusted automatically based on your mash temperature.

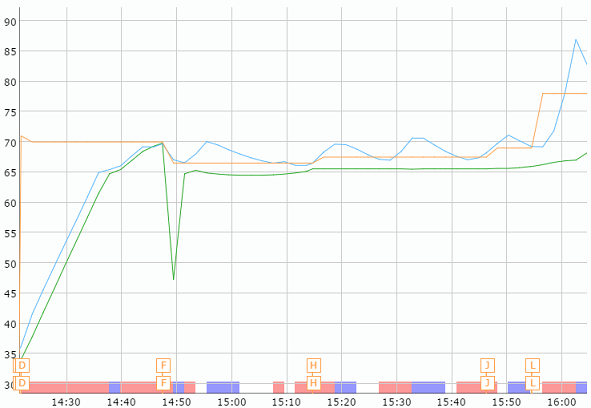

I used the second option in my tests. You can see the results in this chart:

http://chart.brewpi.com/?beername=mash-test6-0.4.0

Unfortunately, in my rental apartment I cannot use heating elements above 3200W, so it is a bit slow to ramp.

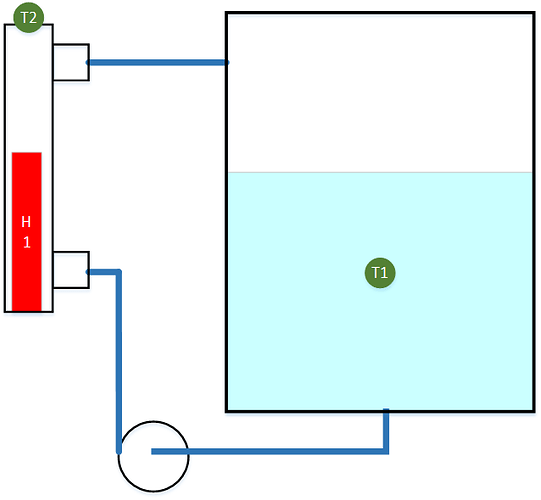

This water test was with 36 liter in the HLT and 18 liter in the mash tun, recircling through a 40cm stainless herms coil and with our 17V brewing pump at maximum speed.

The mash temperature is measured at the MT output, in a tee with our threaded temperature sensor, and displayed as beer temperature.

The HLT temperature is also measured at the output and displayed as fridge temperature.

The MT input temperature is shown as room temperature.

The settings I used are as follows.

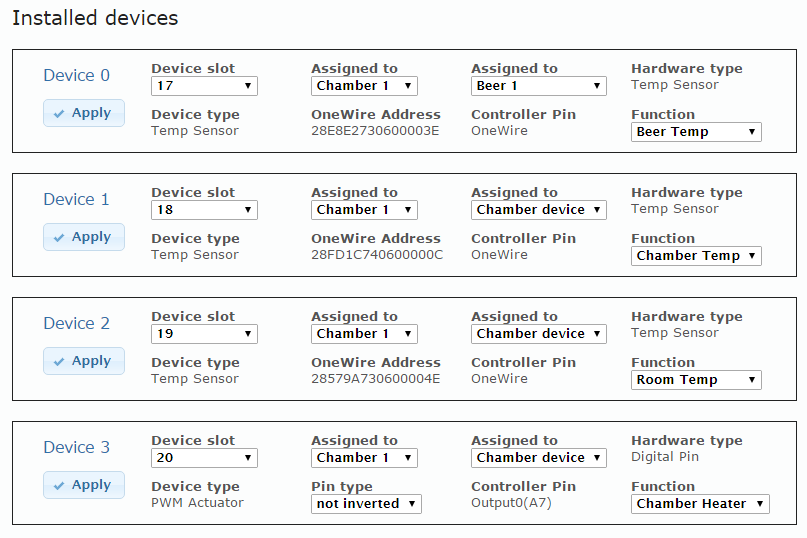

Devices:

I used these high slots, because I want install my motorized valves to 1-12.

Advanced settings

Here you will tweak your controller to work well for mashing.

Beer-to-Fridge proportional gain (Kp) = 0.5

If you want no overshoot, this value should be MT volume / HLT volume.

If the mash temperature is 2 degrees too low, it will raise the HLT temperature to 1 degree above the mash setpoint.

Beer-to-Fridge integral time constant (Ti) = 300

This determines how quickly the integral will raise your HLT setpoint if the mash temperature stays too low. I find 3 minutes works well.

Beer-to-Fridge derivative time constant (Td) = 120

This prevents overshoot. A too high value will create a very slow approach to your mash setpoint. A too low value might cause overshoot.

Maximum difference between fridge and beer set point = 5 C

This will prevent your HLT from going higher than 5 degrees above your beer setting. This also prevents your HLT from going too high and destroying enzymes while the wort goes through.

Beer-to-Fridge Input filter delay time = 18 seconds

A bit of filtering on the beer temperature creates a nice slow setpoint for the HLT

Beer-to-Fridge Derivative filter delay time = 18 seconds

A bit of filtering on the beer temperature creates a nice slow setpoint for the HLT

The cooler and heater2 settings are not used.

Heater 1 proportional gain (Kp) = 50

1 degree Celsius difference will set the heater to 50%. If you have a very powerful heating element, you could go lower. In my tests, you can go pretty high without overshooting.

Heater 1 integral time constant (Ti) = 300

It will take 3 minutes to adjust for temperature losses. The integral keeps my element at around 40% to keep the HLT at temperature.

Heater 1 derivative time constant (Td) = 30

When you turn off the heater suddenly, how long does the temperatue keep rising? I think 60s might be a bit much already.

Heater 1 Input filter delay time = 18 seconds

A bit of filtering on the beer temperature creates a nice slow setpoint for the HLT

Heater 1 Derivative filter delay time = 18 seconds

A bit of filtering on the beer temperature creates a nice slow setpoint for the HLT

Dead time when switching between actuators = 0

There is no switching between actuators, but I have seen a strange event where my mashing setup thought it was cooling for a second. I will investigate this further. Just set it to zero to make sure it does not affect you.