Originally published at: https://www.brewpi.com/what-is-ideal-herms-coil-length-theory-experiments/

Introduction When we started selling HERMS coils 2 years ago, we made our 40cm coil 15 meters (50 feet) long. The 30cm coil was 11.5m long. Why? That’s what most home brewers were doing. But we recently started to suspect that such a long coil is not optimal. Sure, a longer coil will give you…

Also posted on reddit here: https://www.reddit.com/r/Homebrewing/comments/6f106c/we_did_experiments_and_math_to_determine_the/

Thanks for sharing your research and great work! I love when there’s science behind the claims. That 3-way coil looks so cool!

Great work Elco! Sorry on the possible OT but I saw some mentions of this on Reddit, and would like to know your opinion on how could these findings be applied to CFC (ie tube length, increasing flow rate, maximizing contact area etc.)? I was thinking of doing a similar experiment but it was too expensive to start with and there were too many variations in the mix (outer/inner diameter, convoluted copper vs regular one, the possibility of soldering wire in a spiral on the outside of inner tube for breaking of laminar flow, input water temperature etc). What interests me is which parameter would be the most beneficial one to the whole system (flow, area, temperature difference…).

I would like to investigate that, but for me, being able to the manufacture the coils at a reasonable price is also important. I would say:

- No copper, stainless is much more durable. Copper has a higher thermal conductivity, but it will oxidize and turn green and nasty. I have made a copper/silicone and stainless/silicone CFC and the copper one looked nasty after very quickly, while the stainless one is as good as new.

- No wire around the tubing, not easy to make.

- With the diameters and flow rates we’re talking about, you don’t have to worry about laminar flow. It will be turbulent.

So I’m pretty much set on a 11 mm ID, 12 mm OD tube, with a silicone or similar outer tube, 18 or 20mm OD. Mainly have to determine length.

Thanks for the follow-up. A topic from last year (product prototype cfc I think) where you’ve discussed some of these questions was very useful, and I’m in process of building a new one and every piece of advice like this is very useful

Hi Elco,

When will the revised HERMS coils become available in the store?

/Ken

The shorter HERMS coil is already available.

The new 3-way parallel coil will still need to be produced. I only have a few prototypes now, which are already spoken for.

It will take 4-5 weeks before the new high flow coil is available.

Elco

Hi there, that new design looks interesting. Did you run tests on that for which you can share the results? I’m interested to know how it stacks up on paper v the results from the other experiments you did.

Cheers,

Mike

I have ran the test today, we’ll process the results tomorrow.

We need a bit more time to write the blog post update, but I did use the new 3D coil yesterday when brewed.

It was a super smooth brew day due to:

- The new coil working well and giving me higher flow

- Wet milling for the first time to keep the grain husks more intact

- Improvements to the PID algorithm working well

- Improvements to the valve control code working well

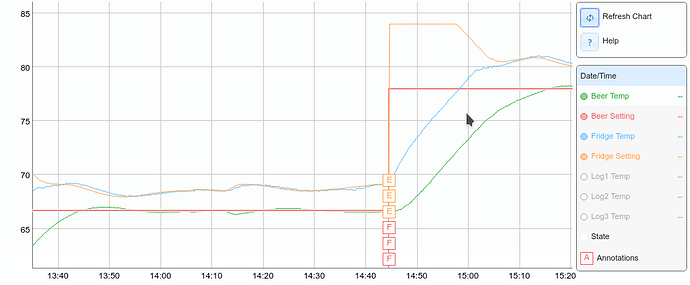

I hit all my targets spot on, including mash temperature:

HLT temp = fridge temp and mash temp = beer temp in the graph above.

Hello, I want ask what ID and OD have the 3-way parallel coil, and what is long of single and all together ? And did u compare this 3-way parallel prototype with standard 7,5m 12mm coil ?

What about installing a mixing device to improve heat transfer rates? Even a slow rotating mixer might help …

Yes, we did some new tests and stirring definitely helps. I now have a whirlpool inlet in the HLT too.

The new fittings for the 3-way parallel coil will arrive this week. We will publish updated measurements on the blog and it will be added to the shop in 2-3 weeks.

I just have U-shaped arrangement of fittings with a quick disconnect that I hook over the top of my HLT. I just pump out of the bottom and back in the top using that. One less breach and one less valve for me to forget to close.

Hello, when do you think is the new 3-way herms coil available? Thank you in advance for your short feedback

I had some other experiences with the old larger discontinued herms coil, I first used the small one, and later on the larger one, and I saw a good difference in temp. I have always had circulation in the HLT, but when I actually used a bit of brain, I turned the outlet on the circulation in the opposite direction of the coil flow, that improved it a a lot as well

That’s a good suggestion too.

I think a big factor is the spacing between the loops of the coils. I’ve just started a new production batch and this time we’ll leave some more space between the individual loops, so the water can freely run between them.

I had to used 1cm hose slices to spacers for every 1/4. That improved it alot because of the optimal surface and circulation.

7 years ago I built a HERMS setup, and used it for a while. In 2014 I had to give the circuit controller back to my company (since it was on loan).

I feel compelled to finally get it all up and running again with an Arduino or raspberry pi.

Ultimately I hope to have as much automated as possible and press a single button to do everything.

My coil is 27 feet of 3/8 inch copper in a double coil configuration with each coil flowing in opposite directions.

Here is my Flickr photo album with detailed descriptions:

Some videos demonstrating the basic operation:

http://www.youtube.com/user/rubikbrewer#g/c/248E5283F7608CBA