That sounds great, thanks. Forgive my ignorance though, as I’m new to this type of hardware. But are you using the MOSFET Board in stead of the SSR’s?

correct!

the SSR is for AC, the pump uses DC. if you have a glycol pump that uses AC you could use a SSR. what kind of glycol pump are you trying to control?

Cool! My pumps are indeed DC 12V pumps. I would love to get rid of the power supply in between. As mentioned, this is new territory to me. Would you have some pictures of your build or maybe a link to a guide?

let me find some pics… you will still need a power supply though, I’m using a LED 12 volt power supply…

Thanks! Ok, but one 12V shared (?) power supply is better than one for each pump.

agreed  I’ve used 1 LED power supply for all…

I’ve used 1 LED power supply for all…

Powering the BrewPi?

apologies, no! i actually have a seperate USB power supply for the brewpi…

Ok - no worries. Quite excited to get this build done

I just ordered the MOSFET from AliExpress. I guess I then need to buy:

1 x BrewPi

3 x Temperature Sensors

1 x Raspberry PI (for server)

What else do I need? Cables between the BrewPi and MOSFET?

why are you getting 3 temp sensors?

what you would need

1X 12 volt power supply, make sure it has enough amps to power the heating pad!

1X MOSFET board

2X (but can also be 4 if you want to be prepared for the future) mosfet heatsink (those suckers can get hot)

some cable (i desoldered the plugs from the board and soldered the wires directly on it, the connectors are very, let’s say, chinese.)

1 Thermowell temp sensor for in your fermenter

additional temp sensors to measure glycol if you want to, but not needed

1X brewpi

1X raspberry pi

1X raspberry pi power supply

1X usb cable between raspberry pi and brewpi.

you might want some additional stuff, for instance, i also bought some of the female plugs for the SS Brewtech pump and heater pad so I could just plug them in and out, but that’s up to you.

Thanks a bunch for the pics and parts list!

Three sensors because I would wan’t one for each of my two fermenters (make use of the existing thermowell) and one for the Glycol bath.

Your pictures and parts list raises some questions. The MOSFET heatsink, is that mounted in your picture?

The cables between the BrewPi and MOSFET looks like they are special cables that click into the MOSFET connector. Is that correct?

It looks like you have 6 cables going out of the MOSFET.

From Left to right on the second image:

- Thin black : Power supply?

- Thick black: ?

- Thin red: ?

4: Thin white: ?

5: Thick black: ?

6: Thick black: ?

Btw, I would not be using a heating pad. How would that change my setup?

Thanks in advance

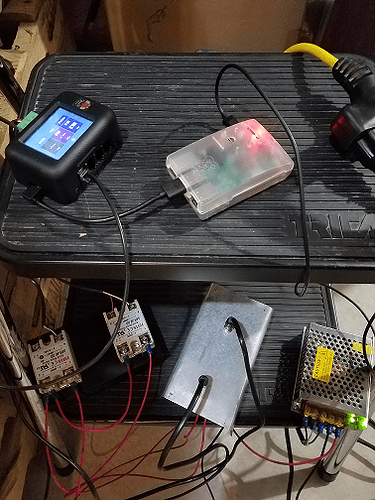

sorry, this was all pre-cleanup and using some breadboard wires

please note that brewpi only does 1 fermentation chamber per brewpi this time… so you can only use this for 1 setup! I know Elco is on working on it though…

anyway, for the rest, no this was a test setup, no MOSFET heat sink is installed here yet. I have cleaned this up and build this into an environment, and this now has the heat sinks.

as far as the cables, this was a test setup so i used some breadboard cable. in my final build I just soldered the connectors off and soldered the cables in directly.

anyway, you only need the outer 2 connectors on the MOSFET side, not the middle one. they both go to the digital out of the brewpi.

on the outs, the first 2 are the + and - of the power supply. unfortunately the screw was broken for me, so I had to place this in the second input. the thick black is the + out for channel one, the second black is the - out for channel 1. then channel 2 etc. the thin red wire was a fix from me since the screw was broken, but should have gone in the very first input (that’s empty in my picture.

ok, so no heating pad. what do you use for heating?

Any idea on when multi chamber support will be released?

Regarding the MOSFET board. Is it as simple as this:

Output:

- The first two power connecters should be connected to the 12V power supply powering the pump

- Channel 1 - Pump cables

- Channel 2 - Heater cables

I dont ferment any styles that needs heating. Do you use heating to avoid overshooting when cooling? If so, won’t the cooling and heating fight each other from time to time?

you are correct on the cables. you will then have to configure channel 1 for cooling, channel 2 for heating in brewpi.

brewpi manages both heating and cooling, so i never had an issue with overshooting or fighting. my shed can be really cold so i might need heating.

SSRs are available for AC and DC Control. I use them in my setup instead of MOSFETs. It comes down to preference.

Hello,

First post here - this thread is exactly why! I am anxiously awaiting delivery of my 1BBL jacketed conical from Stout tanks, and have been researching glycol systems and their controls. The SSBrewtech system looks solid; but as others have pointed out I can get it cheaper with an included pump:

So my thoughts are a BrewPi Spark with three temp probes- Fermentation Temp, Room Temp, Glycol temp. SSR on the fermentation temp control to switch the pump on/off. The Glycol chiller maintains the glycol temp by itself.

And a bunch of tweeking!

Sound about right ?

Thanks,

Steve

Steve,

I am waiting for my SS Glycol to be delivered and I will try to use BrewPi to control the fermentation process. Where you able to set up your system and run it without any temp fluctuations? How many probes are you using for one conical? How are they installed?

Cheers!

Ok - pardon the newb questions - I have basically built my DIY Glycol Fermentation Chiller based on: https://www.longislandhomebrew.com/wp-content/uploads/2016/08/DIY-Homebrew-Glycol-Chiller-David-Kucko.pdf

I’m looking for some specific details:

Wiring schematic for the RPI/Brewpi Spark v3 to the AC unit. so I in the brewpi (somehow) i set my Temp for the fermenter once that is reached the unit should turn off. What parts do i need? Amazon link anyone?

My Current AC unit that I have has a remote (which i don’t want to use, I want the RPI to manage it. And a circuit board for the temp, fan etc.

Looking for any support / direction would be GREATLY appreciated!