@Elco, I have ordered a new Raspberry Pi power supply, usb cord, new separate power supply for the BrewPi, and upgraded to a RPi 2 from an old B because the USB power is known to be temperamental. I should know how that works out by Friday. I am doing this to hopefully rule out any suspicion that something I have done in the setup of the system is wrong. I believe that there is either a bug(s) in the firmware when used on the Spark/Photon, I have faulty temperature sensors, or the BrewPi mainboard is somehow malfunctioning.

It’s hard to know if there is a bug because there may only be a couple people here with a complete Photon based BrewPi fridge build that are active on the forum.

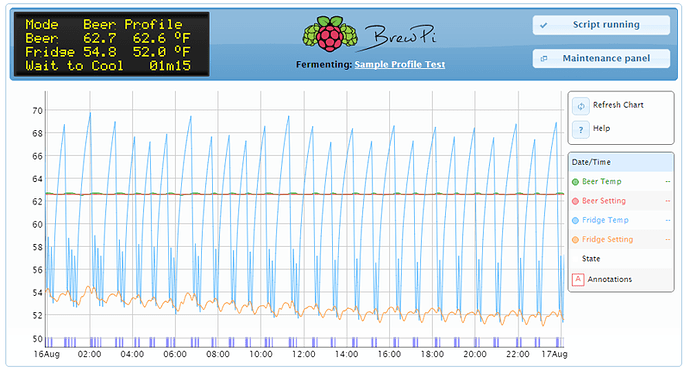

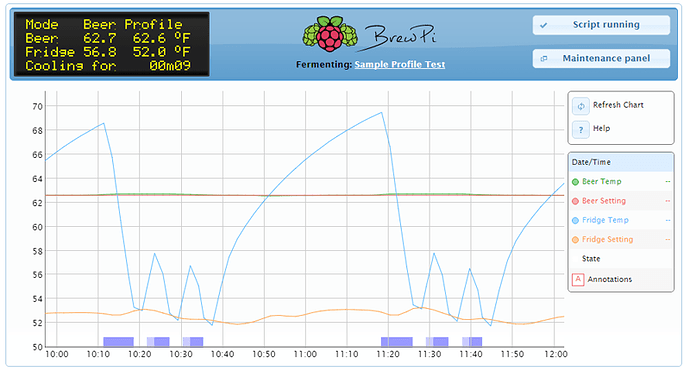

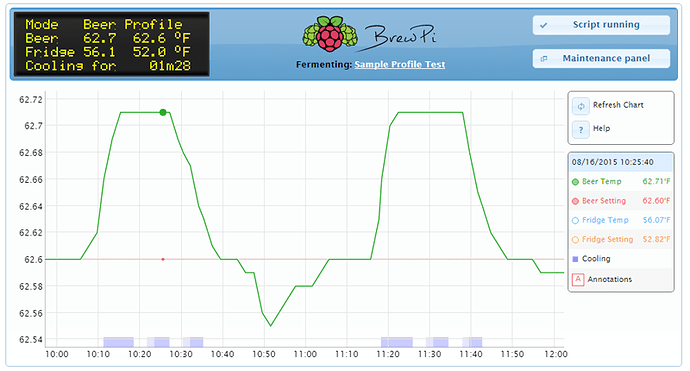

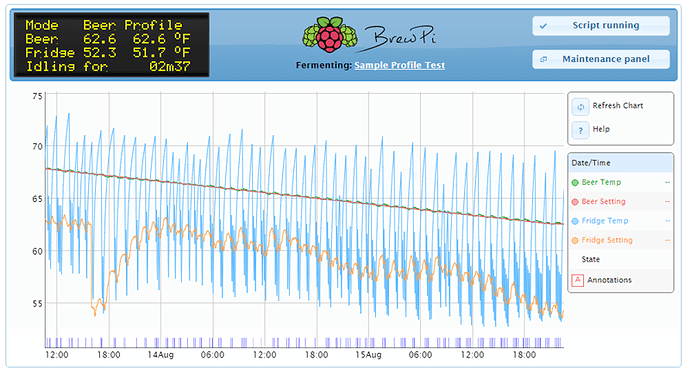

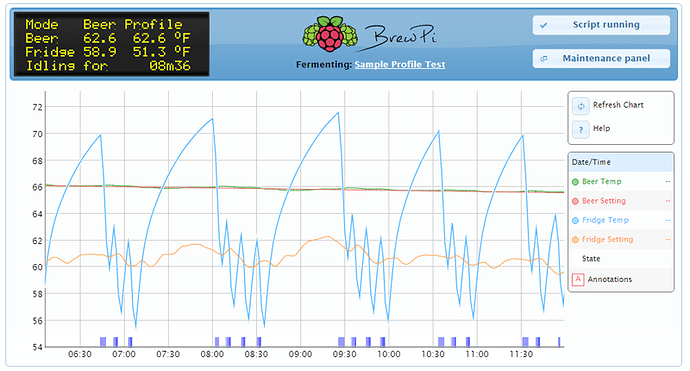

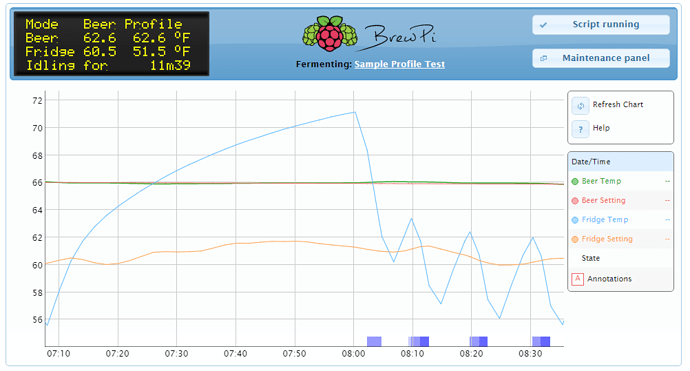

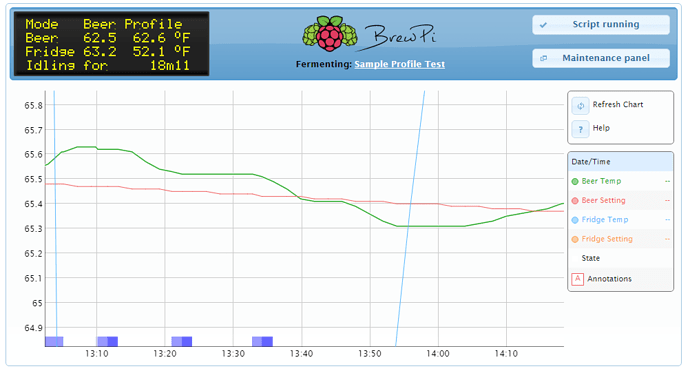

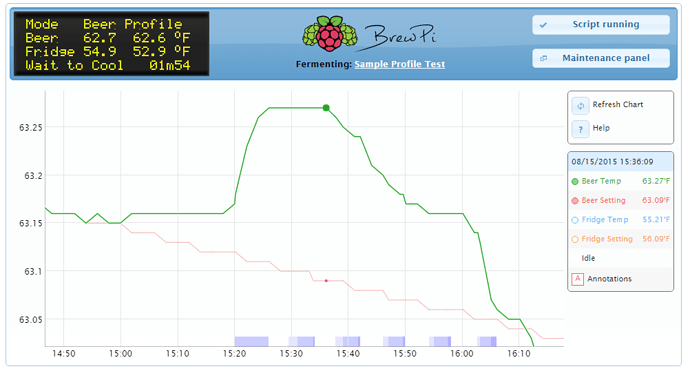

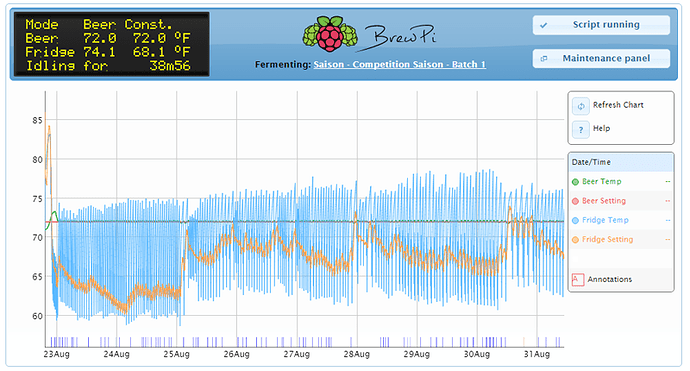

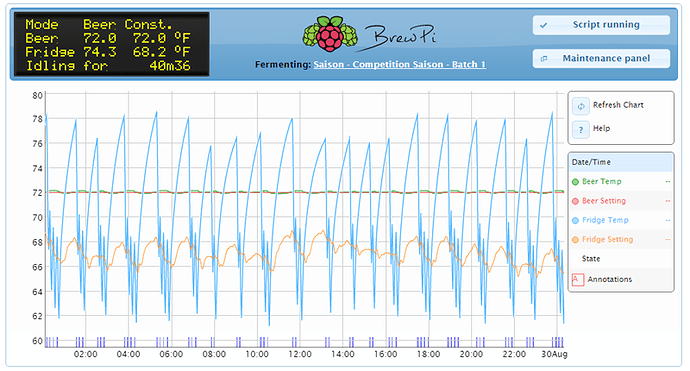

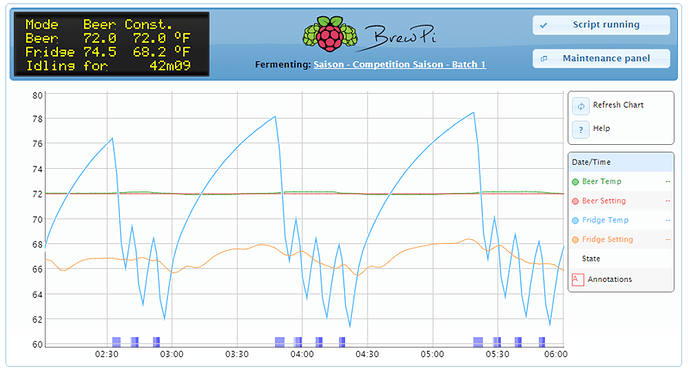

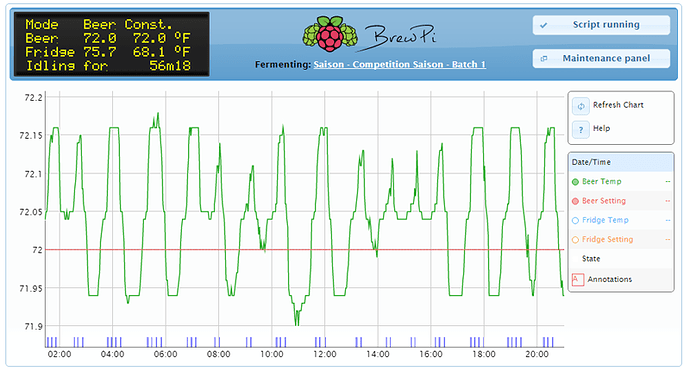

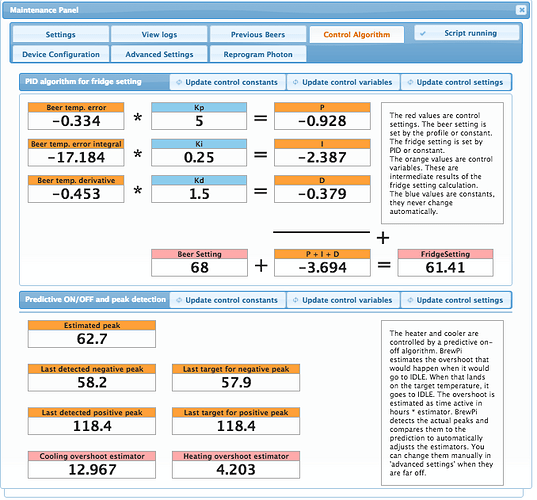

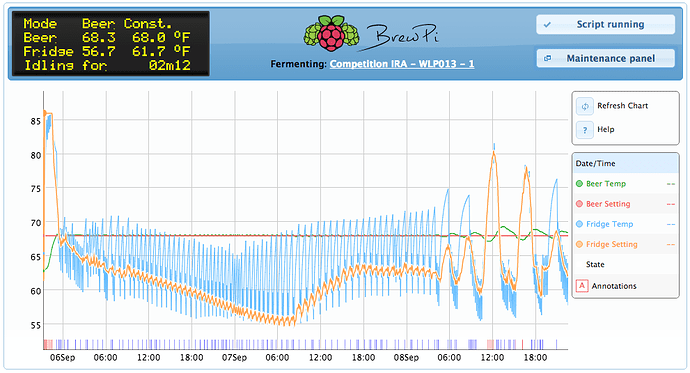

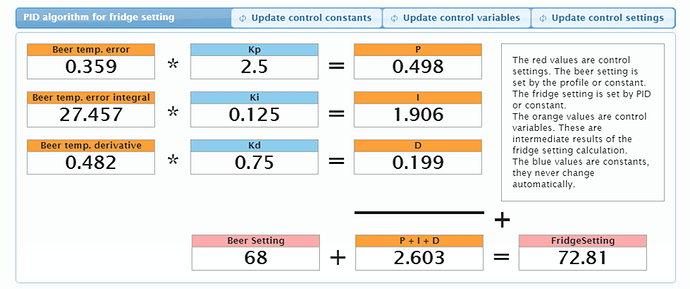

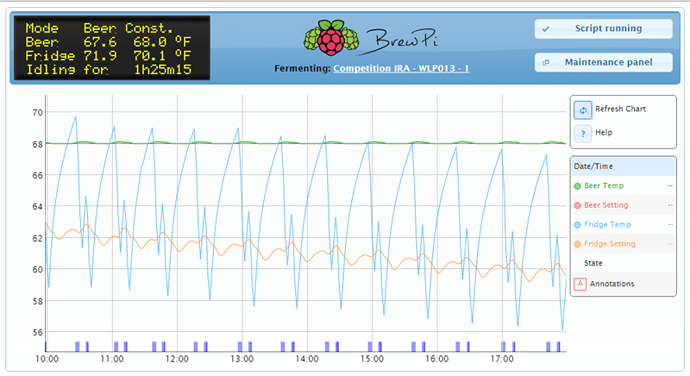

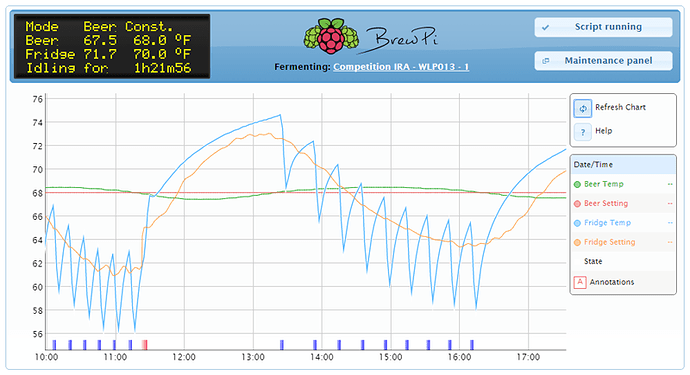

The fermentation starts out fine and I get the accuracy advertised (± 0.1°C) and then the pattern changes seemingly randomly, like I have shown, resulting in loss of accuracy in the form of oscillation of up to + and - 1°F that persists until a new fermentation is started. Normally this wouldnt be a big deal if that oscillation happened over a day or so but with a high powered PID system this oscillation happens repeatedly and quickly. I think it could very possibly lead to undesirable consequences in flavor if this were to happen during the initial phase.

I will report back as soon as I have some actionable information.

Here is the tail of stdout. I haven’t seen any errors reported in stderr

Sep 30 2015 23:21:36 {“BeerTemp”: 71.77,“BeerSet”: 71.56,“BeerAnn”:null,“FridgeTemp”: 71.60,“FridgeSet”: 70.19,“FridgeAnn”:null,“State”:0}

Sep 30 2015 23:22:49 {“BeerTemp”: 71.79,“BeerSet”: 71.56,“BeerAnn”:null,“FridgeTemp”: 71.83,“FridgeSet”: 70.02,“FridgeAnn”:null,“State”:4}

Sep 30 2015 23:24:04 {“BeerTemp”: 71.78,“BeerSet”: 71.56,“BeerAnn”:null,“FridgeTemp”: 70.55,“FridgeSet”: 69.97,“FridgeAnn”:null,“State”:8}

@Elco, would a bug in filter initialization also cause the Control Algorithm page to incorrectly report the math operations being done? This is what worries me most as it makes my changes to the PID constants almost blind. Do you currently have a Photon BrewPi fridge set up with the latest public release firmware to confirm or deny my suspicions? Also, is there a flag I can set to get more complete logging for debugging these kinds of issues?

When this problem is solved I would like to start a thread on BrewPi system debugging to standardize the problem solving process.

I realize you have a lot going on with both the product and business side of the project so I’m trying my best to accurately report back with my findings and autonomously problem solve but I can only do so much with the spare time I have. I would love to be able to just dive into the code but I have been pretty busy at work.

Thanks